This is how we produce unique solutions that fit for a wide range of industries, such as aviation, automotive, mechanical engineering, tool construction, medical technology, contract manufacturing companies, chemical industry, etc.

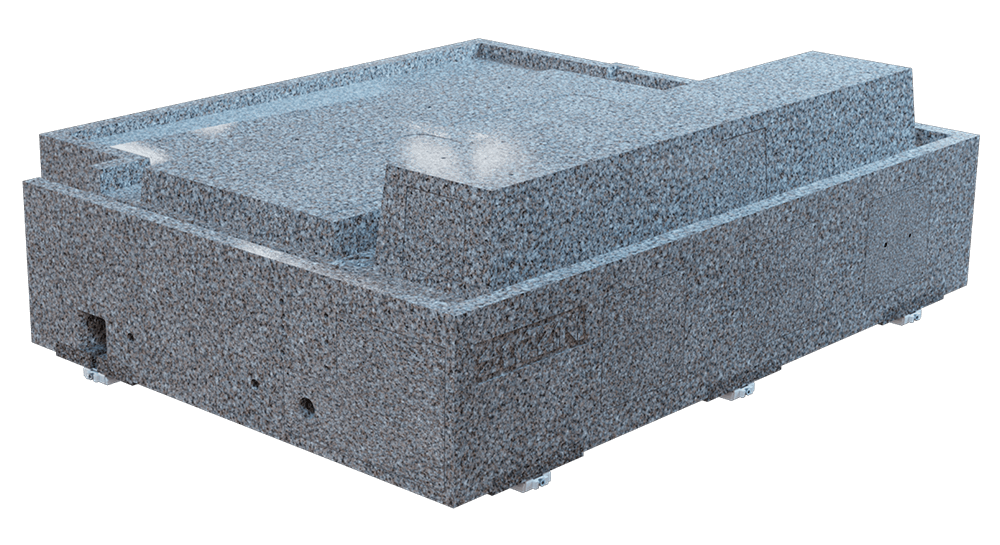

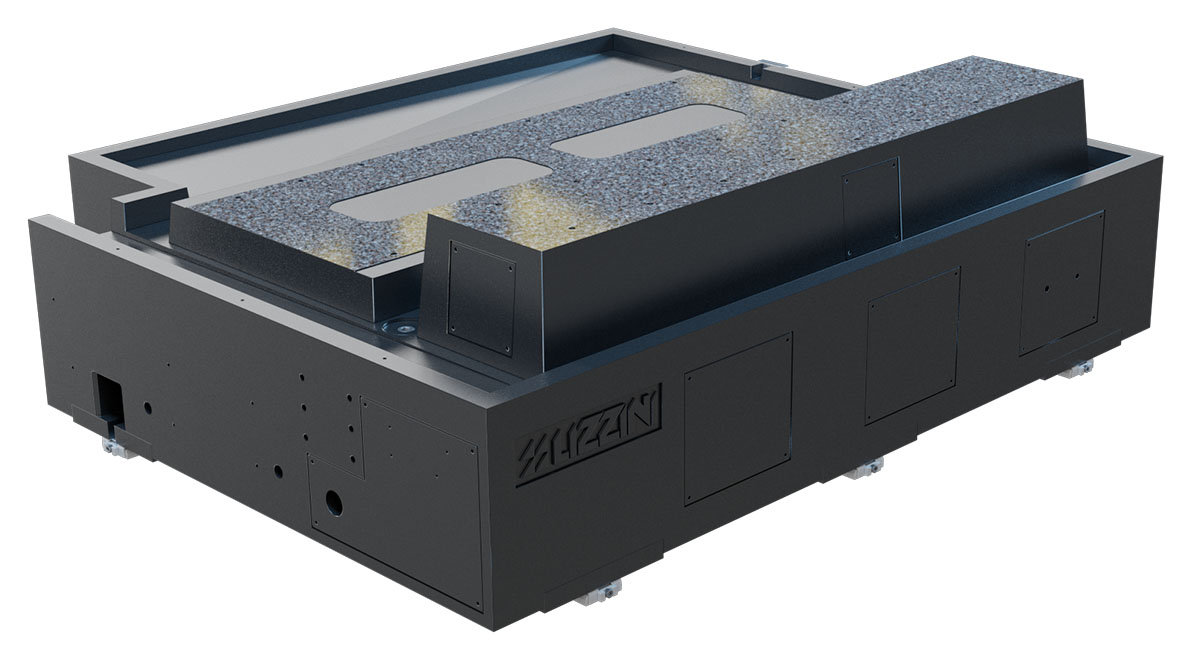

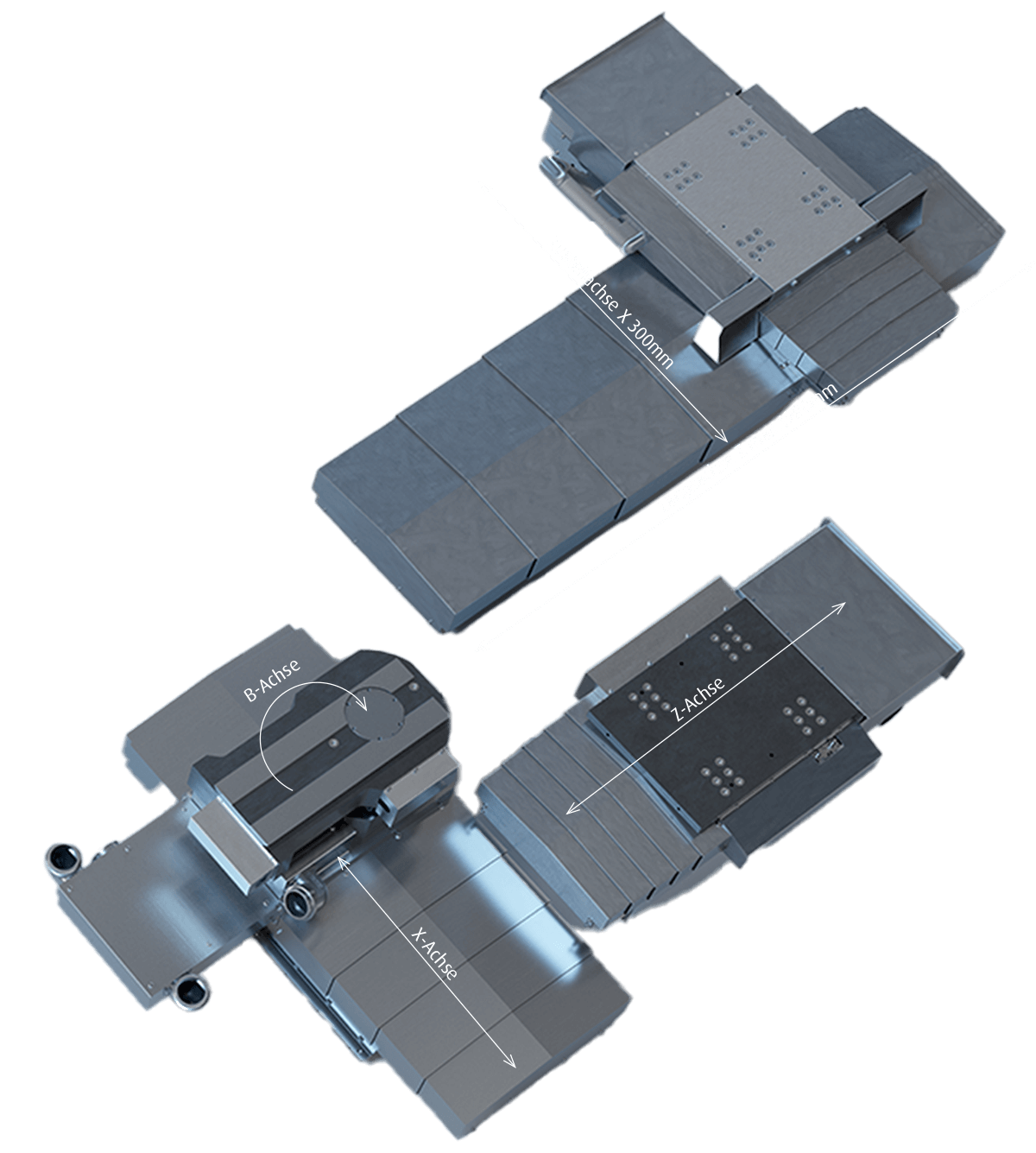

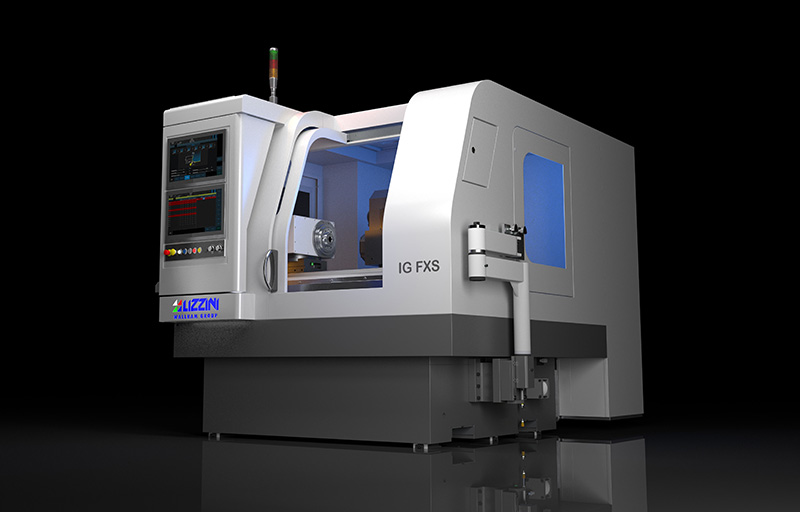

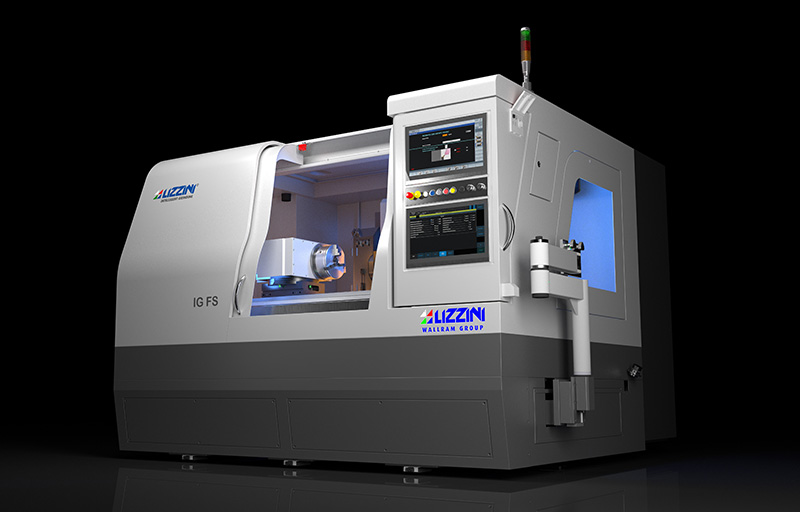

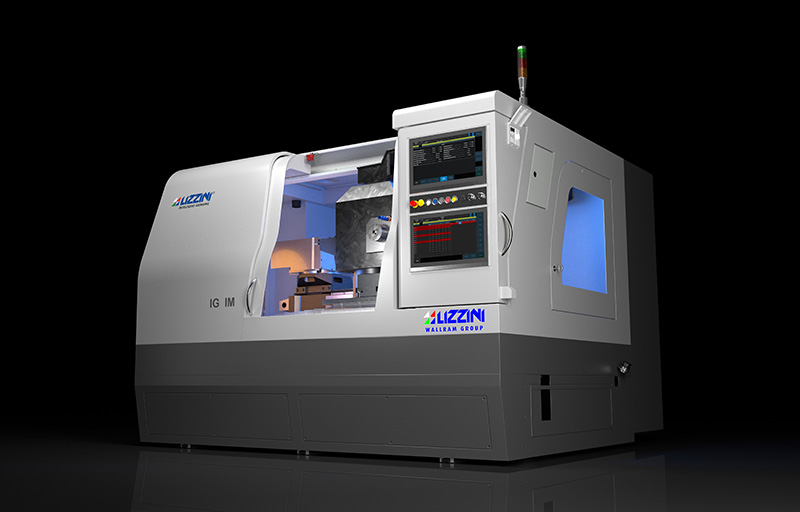

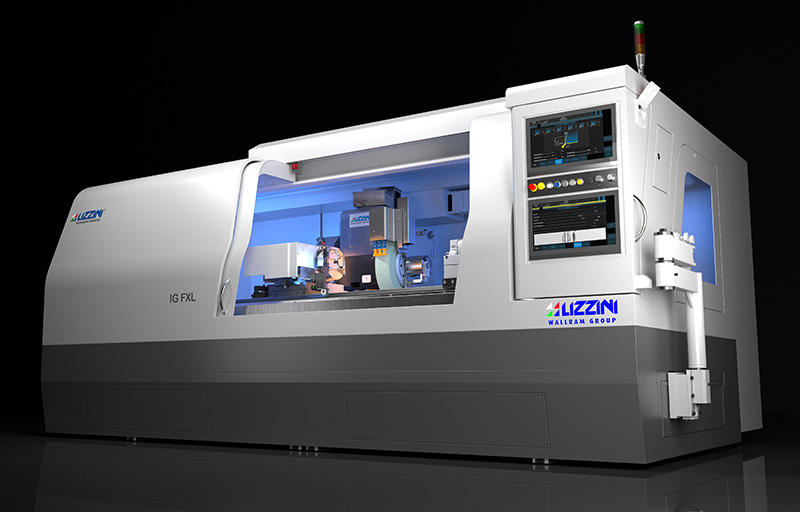

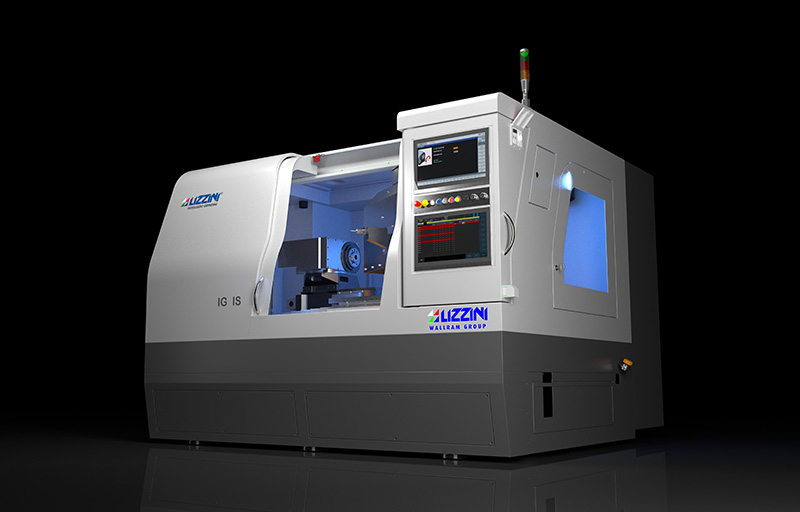

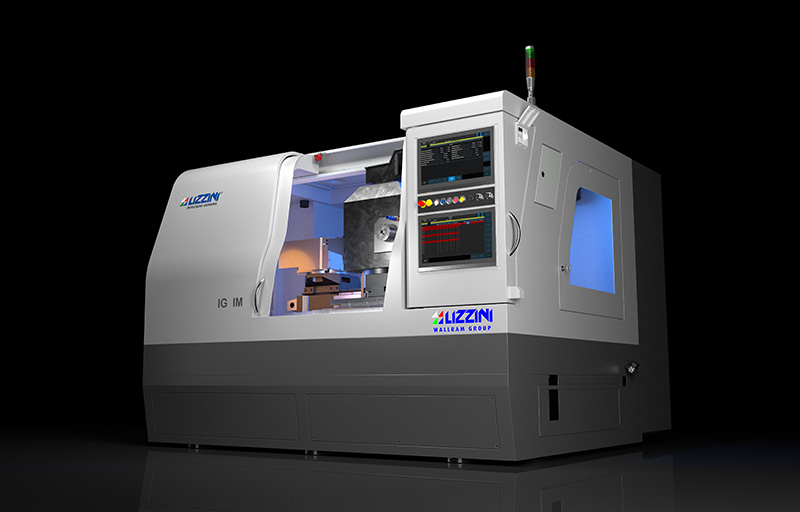

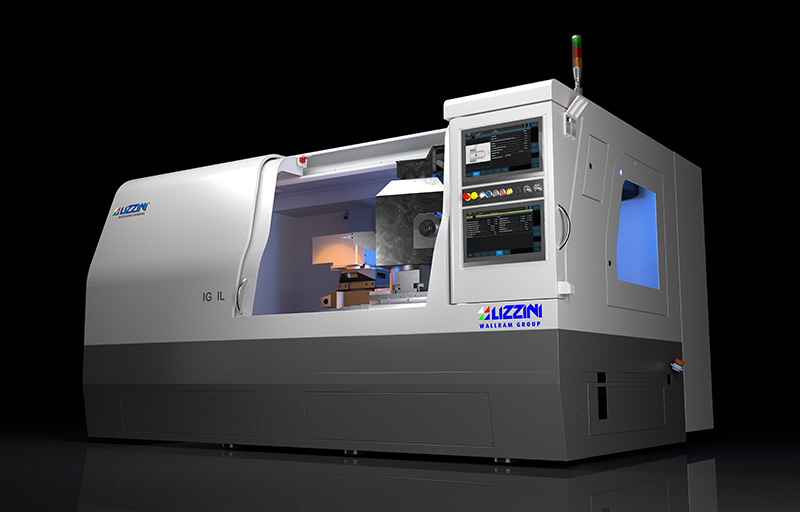

Lizzini’s portfolio for cylindrical grinding comprises eight models: five external/universal grinding machines and three machines for internal grinding. The maximum grinding length range goes from 250 mm (IG FXS) to 1.500 mm (IG FXL). In the middle, we find the IG FS, IG FM and IG FL models, suitable for grinding parts of 500 mm, 800 mm, 1.000 mm maximum length. Our machines for internal grinding are suitable for grinding parts up to 300 mm length and have a center height of 230 mm. The bed of the internal machines is in natural granite as a standard, in order to ensure the best thermal stability possible and, consequently, maximum precision.

All our products are tailor-made, according to customers’ requests. Thanks to their flexibility, our machines are suitable for a wide range of processing.

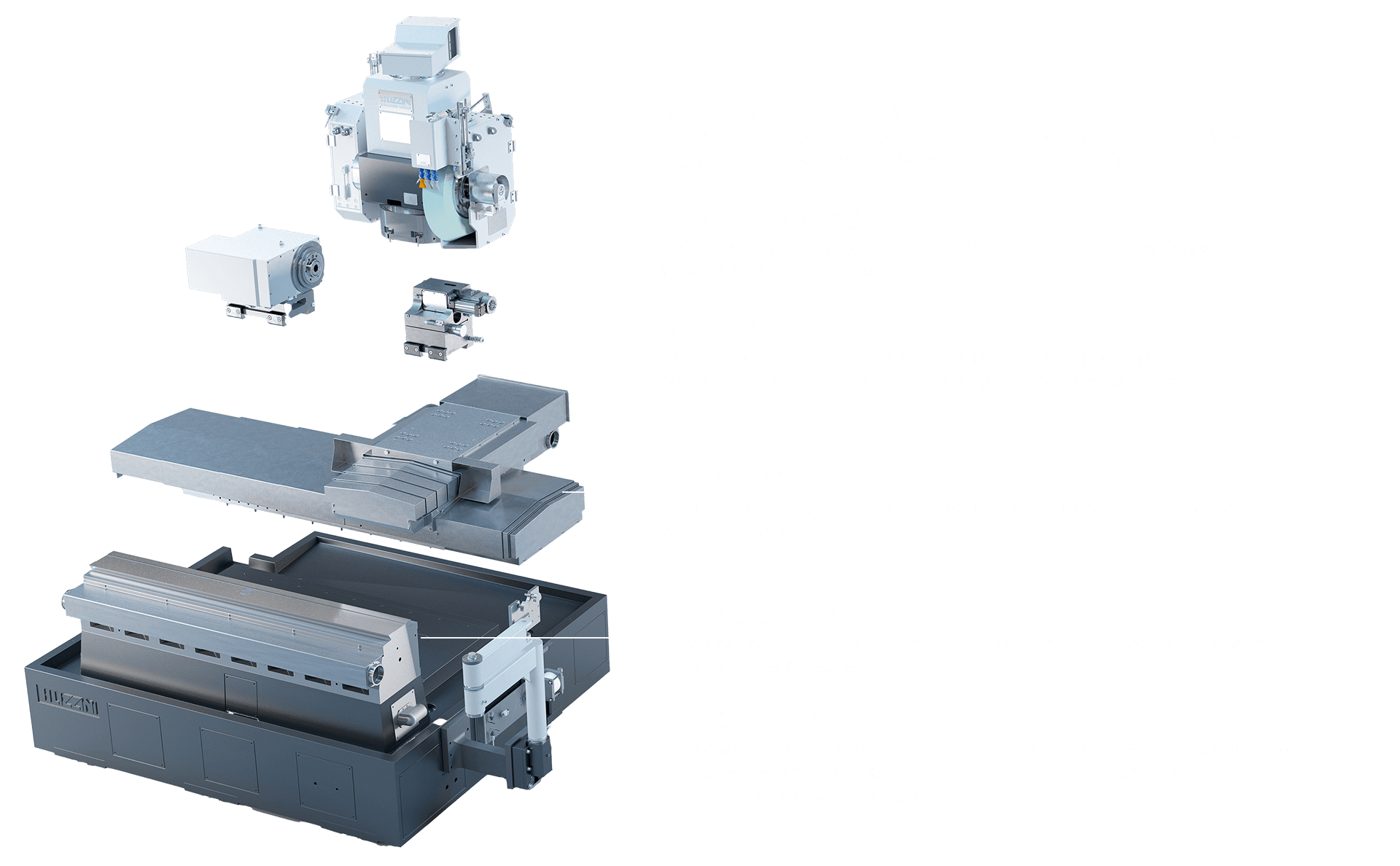

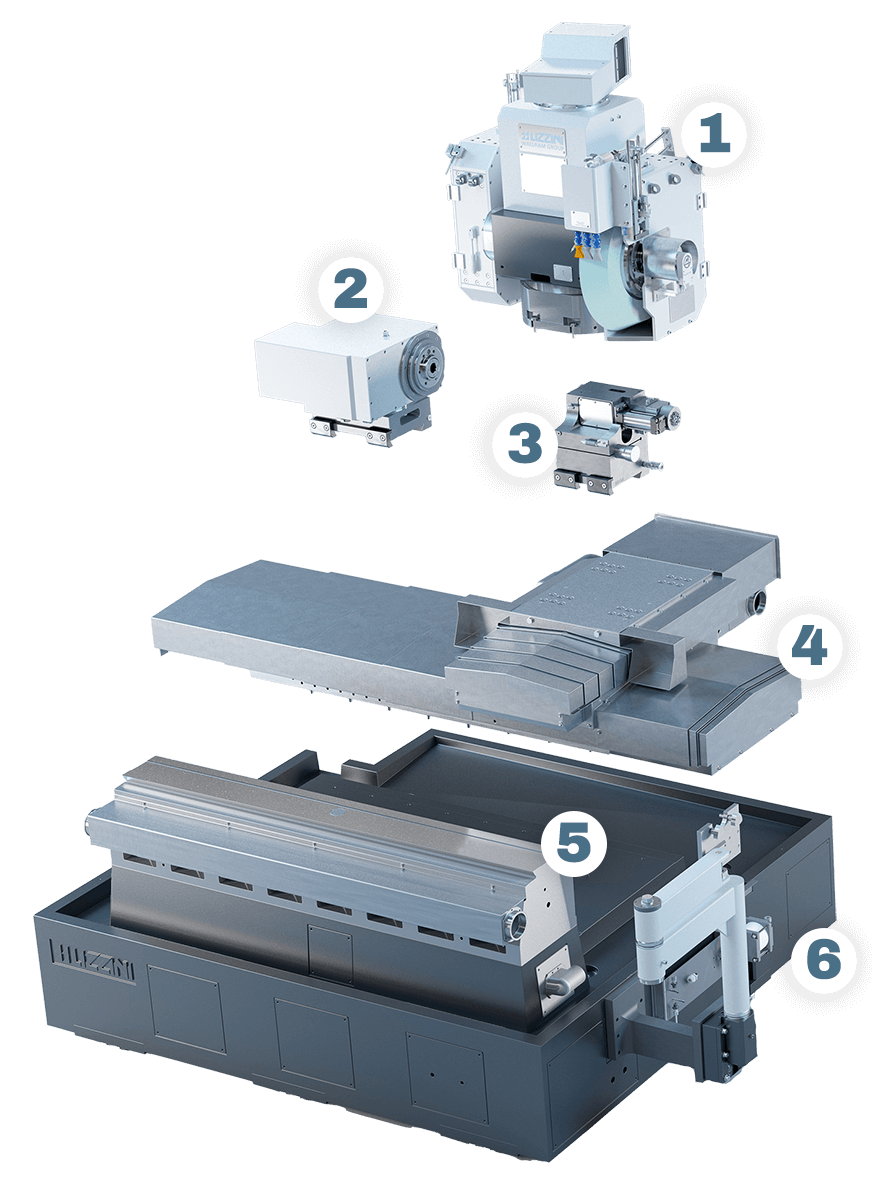

There are many optional available: natural granite bed, B axis, software implementations, linear motors, hydrostatic guides, balancing and measuring systems, dressing systems, automation…

Take a look at our portfolio to find the model that best fits your needs.