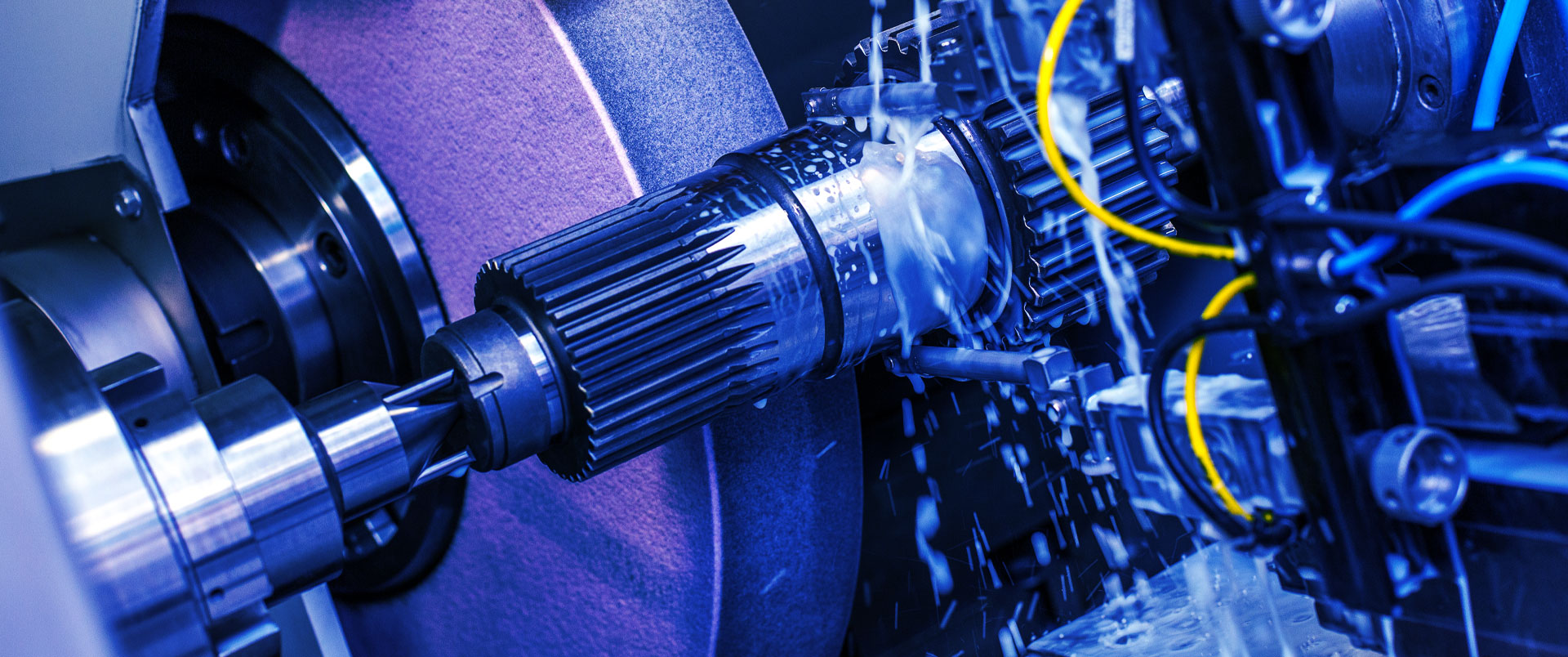

- Grinding machines

- Grinding machines overview

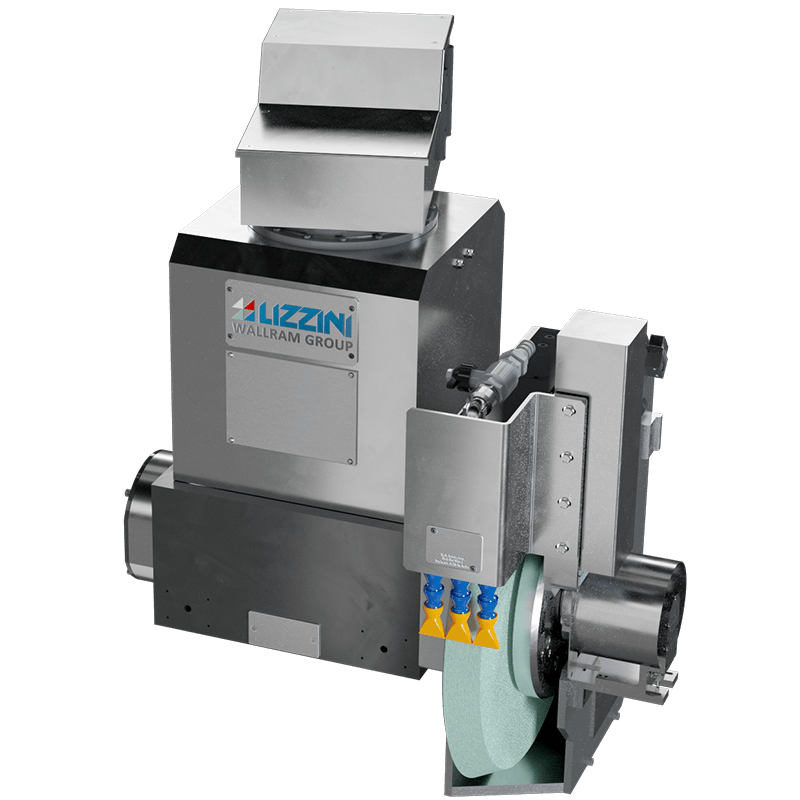

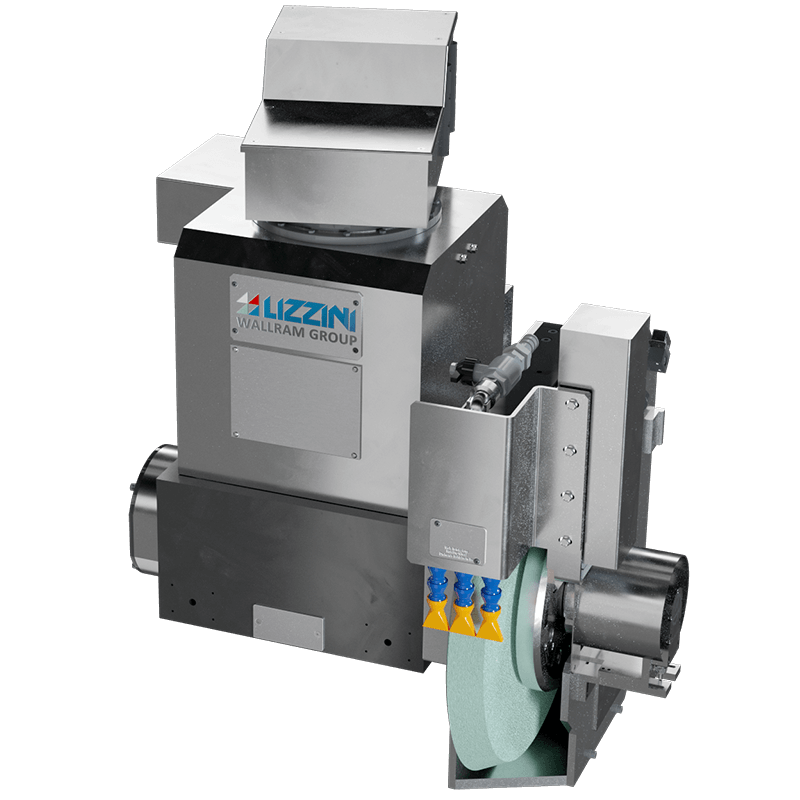

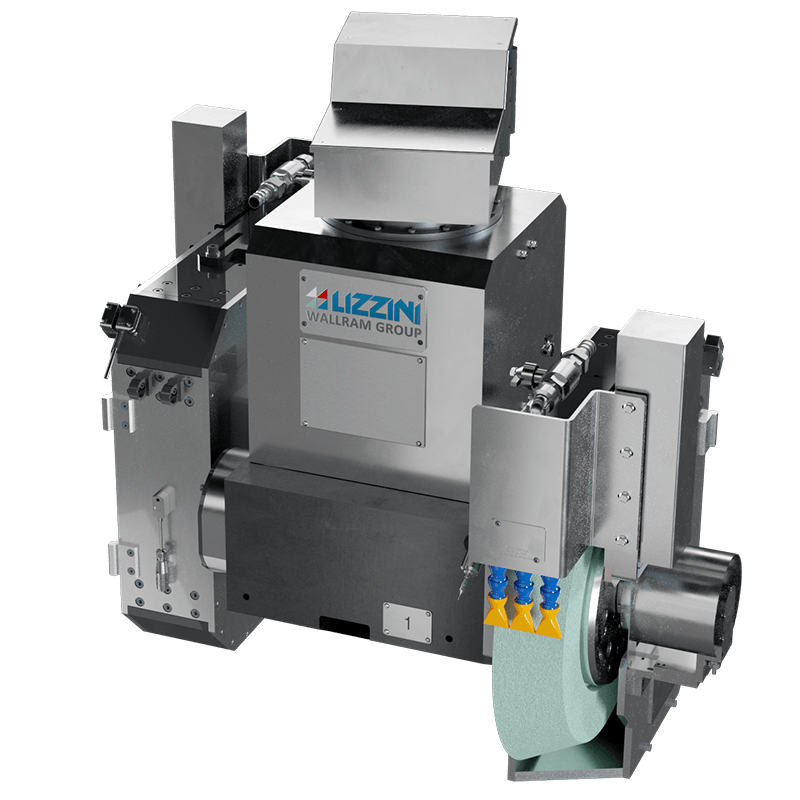

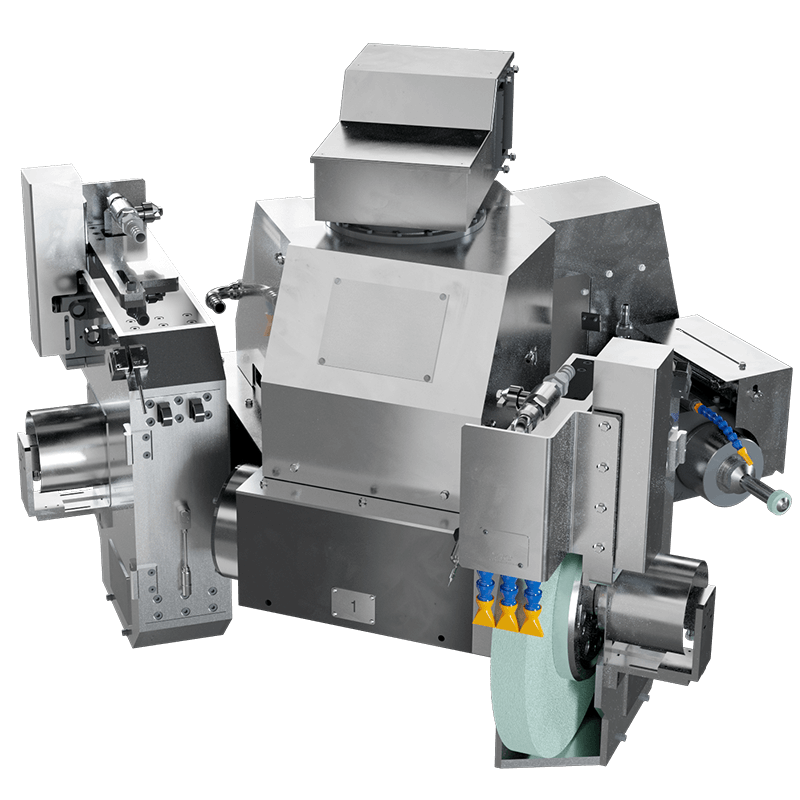

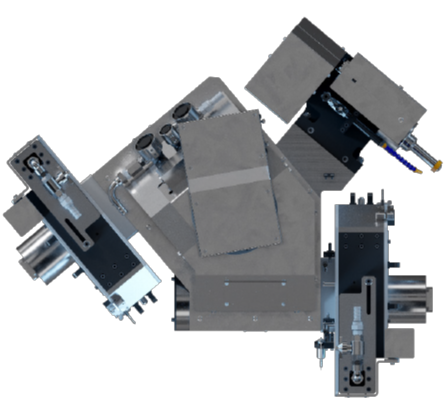

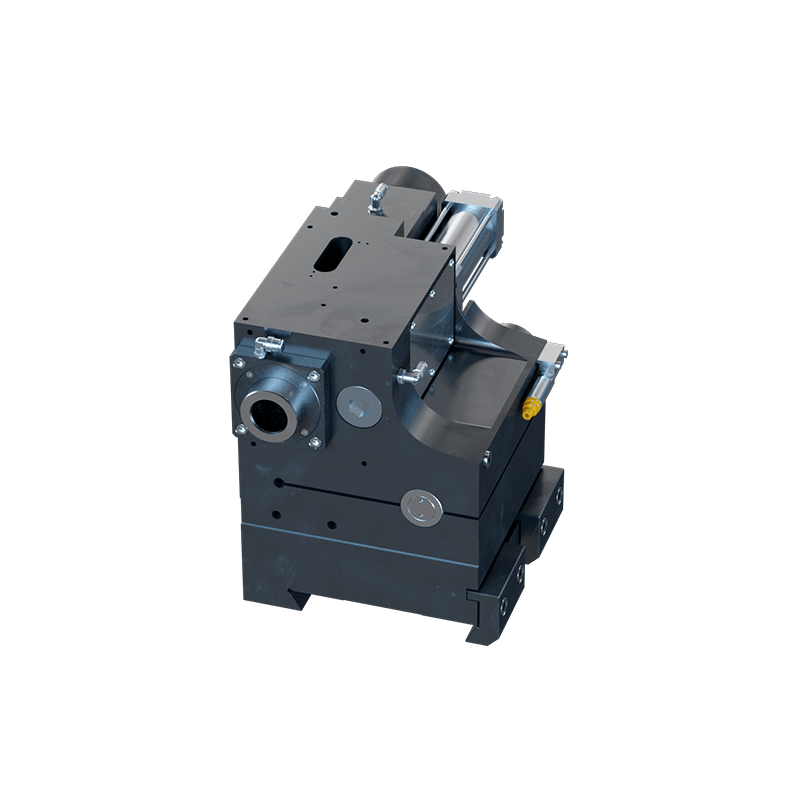

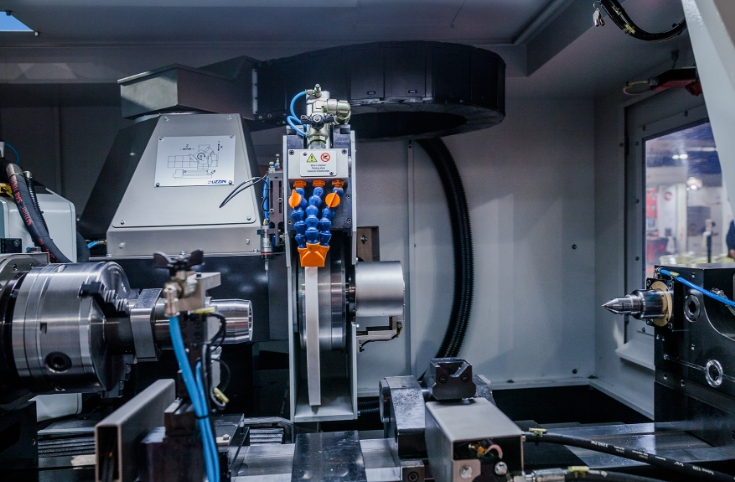

- Cylindrical grinding machine IG FXS

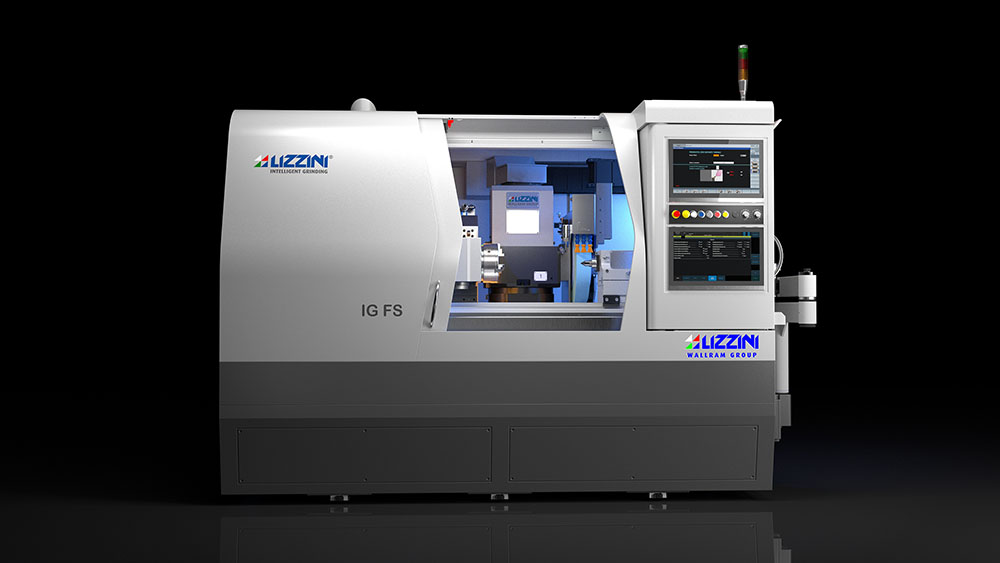

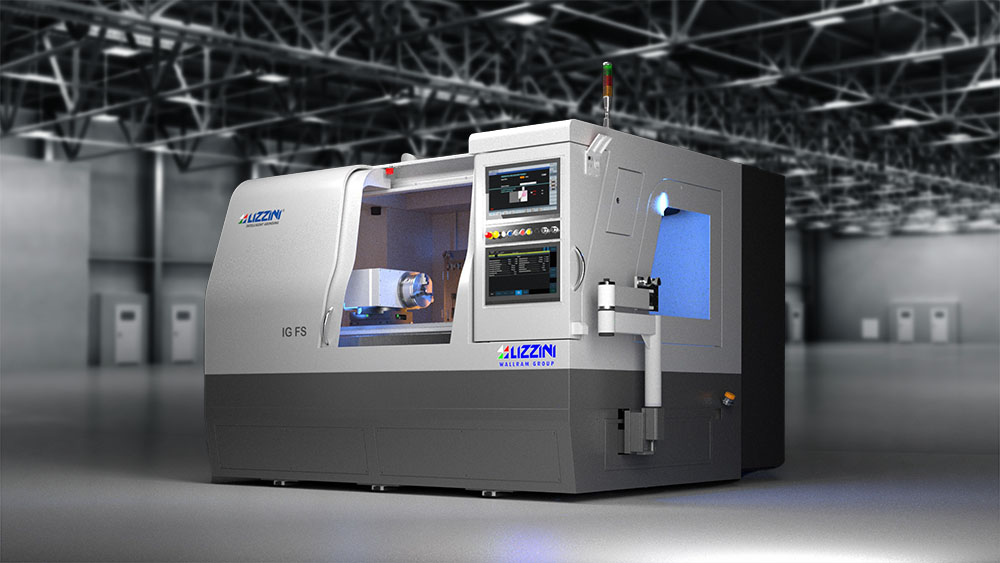

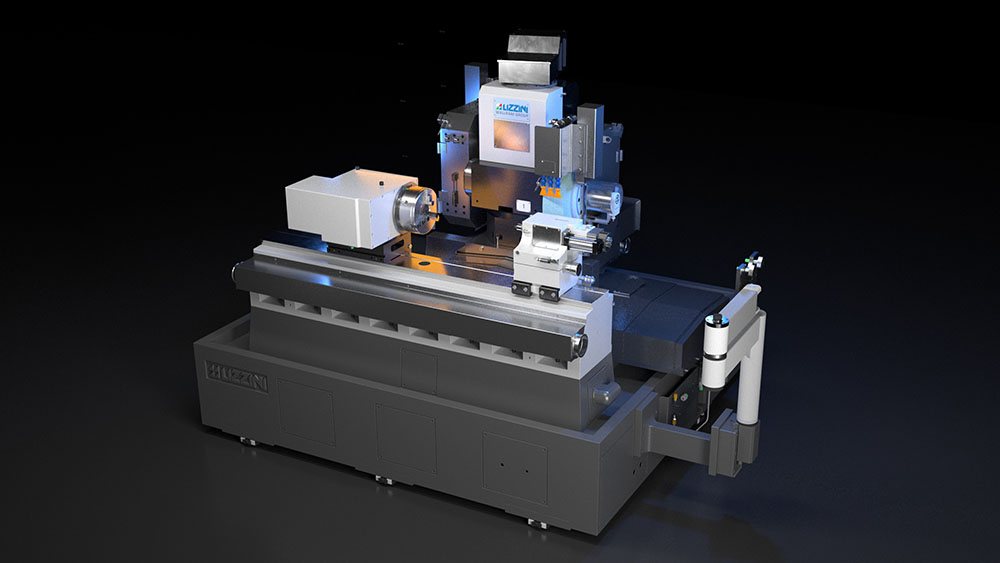

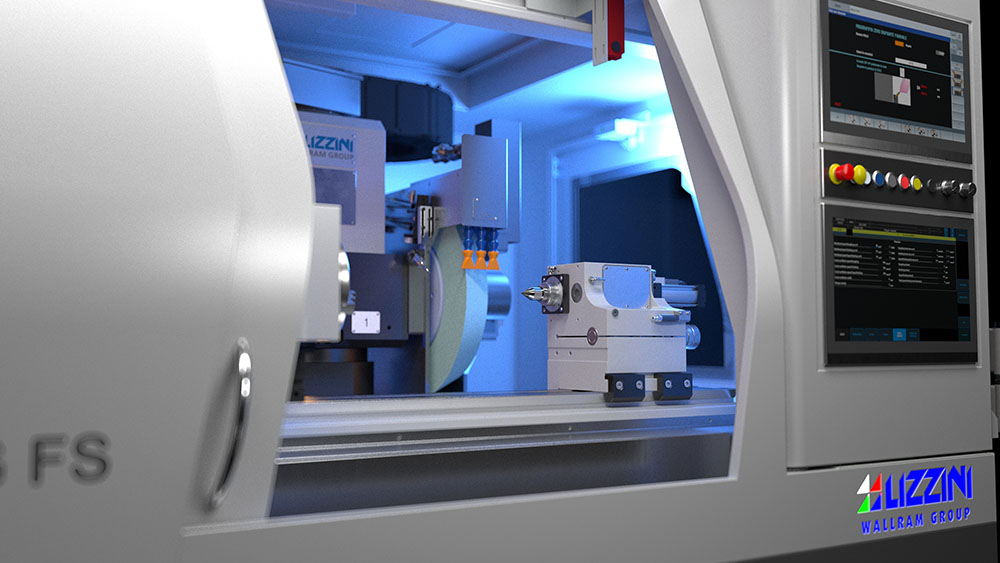

- Cylindrical grinding machine IG FS

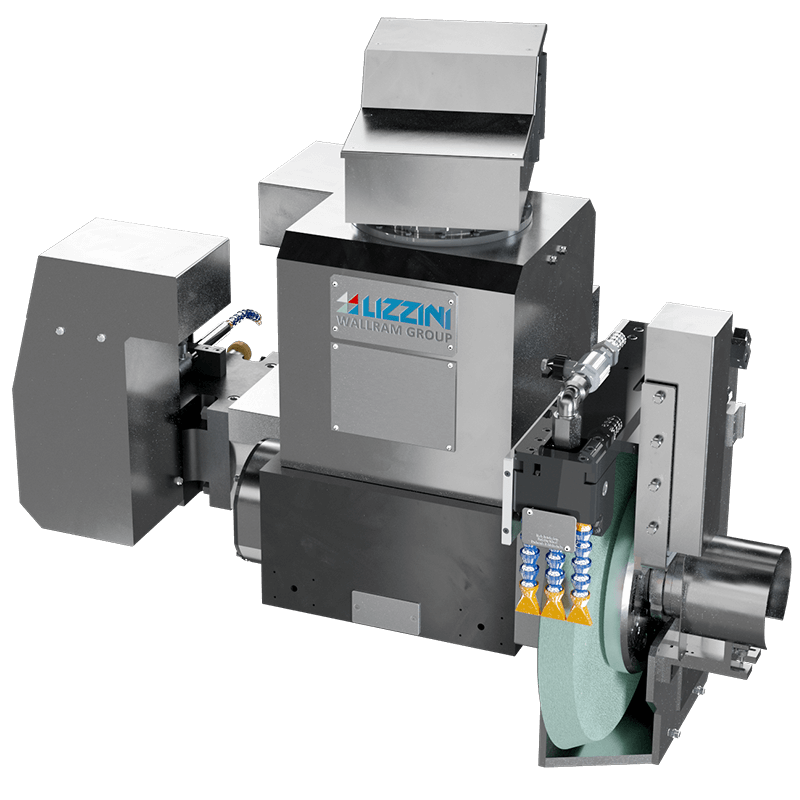

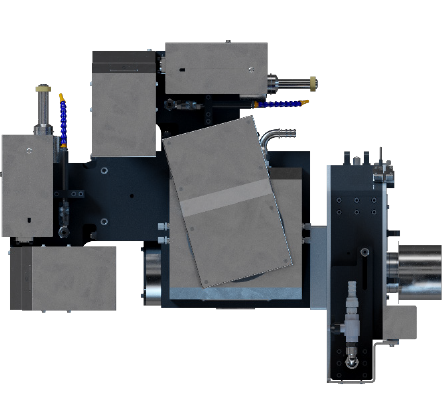

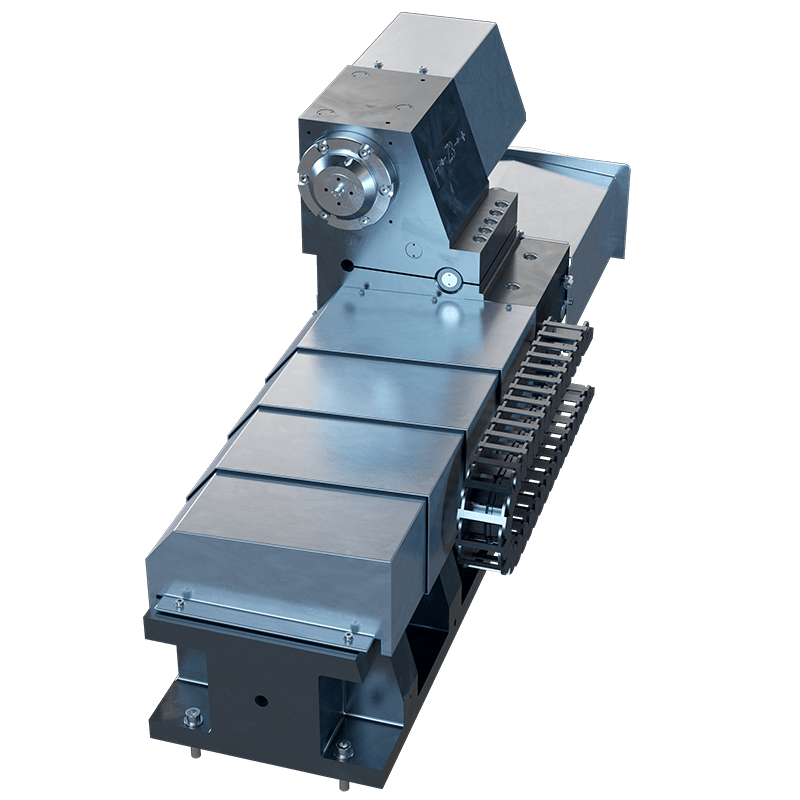

- Cylindrical grinding machine IG FM

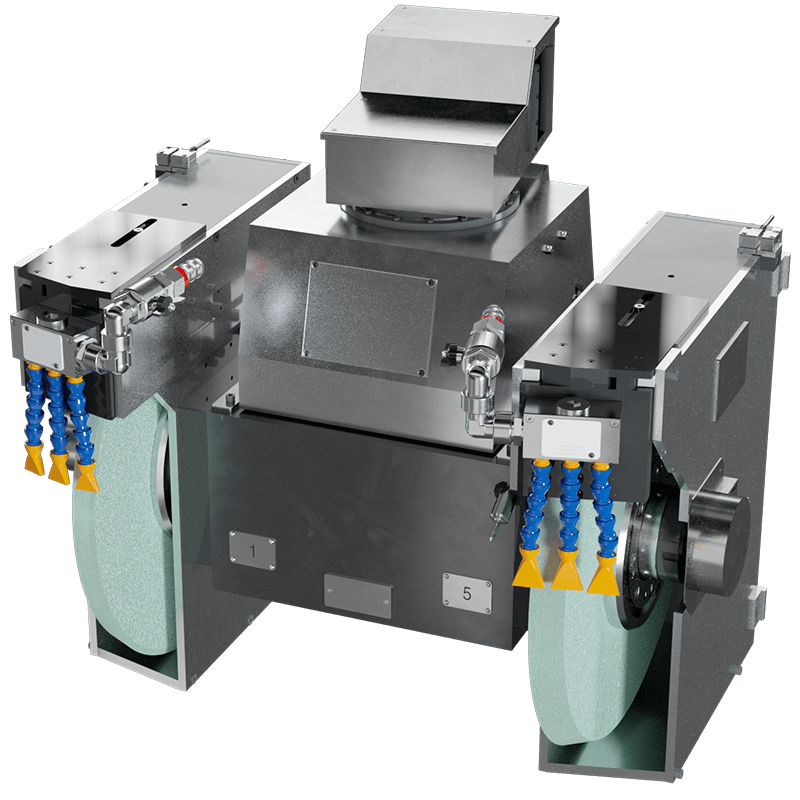

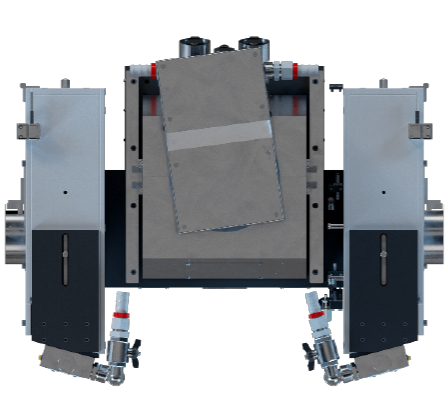

- Cylindrical grinding machine IG FL

- Cylindrical grinding machine IG FXL

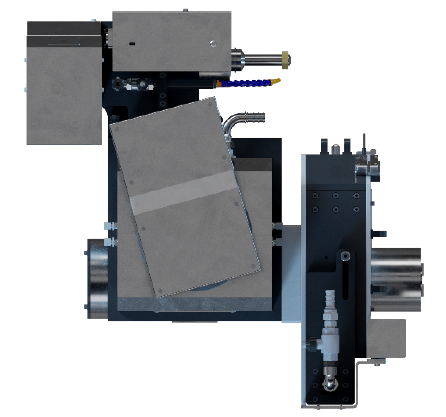

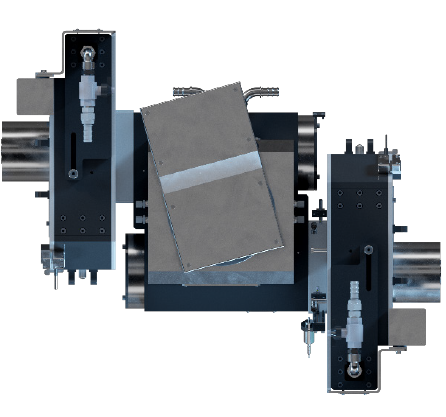

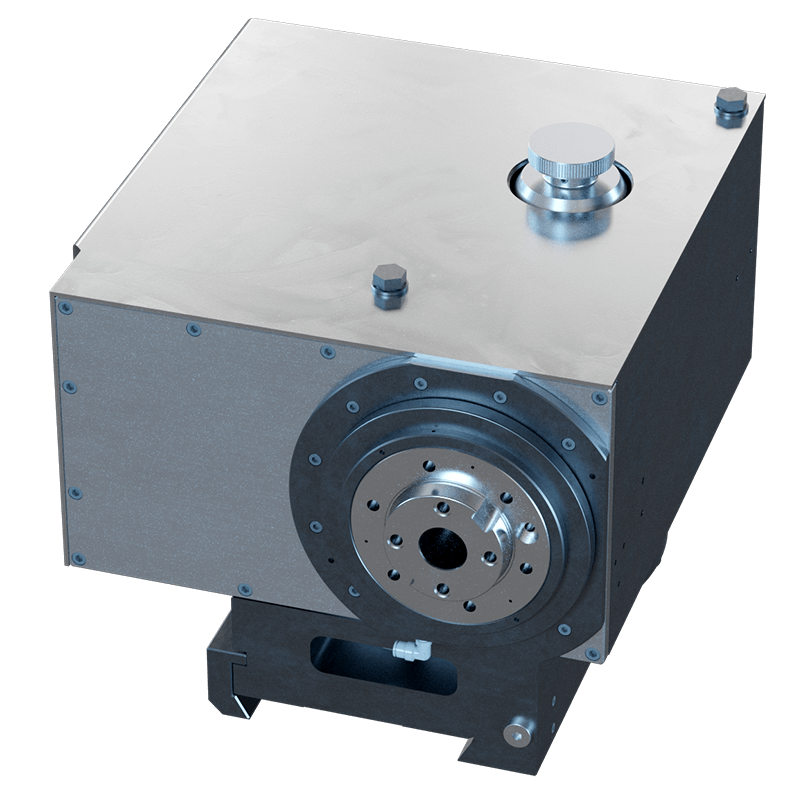

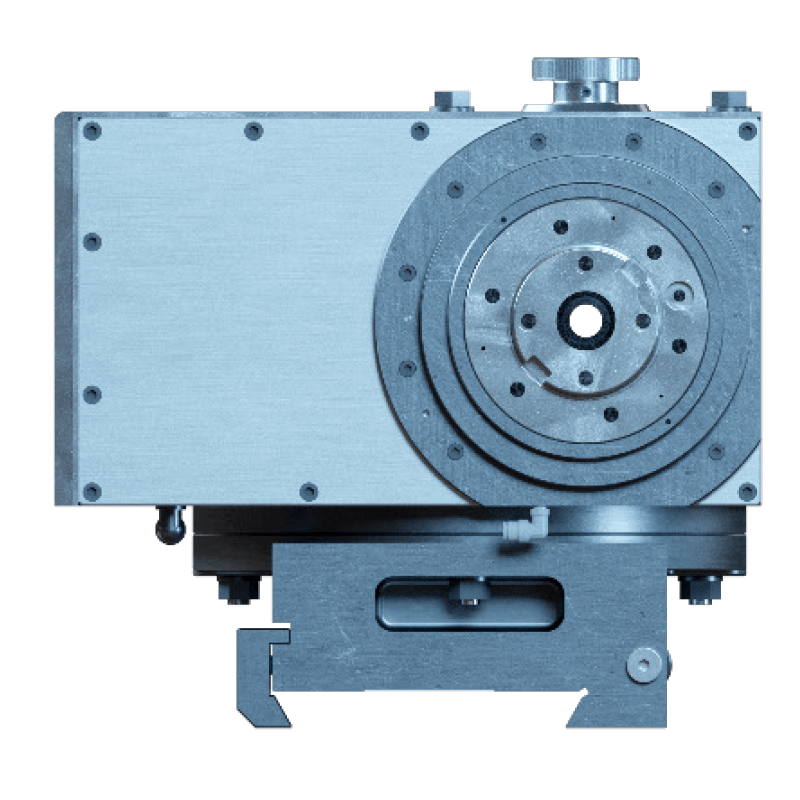

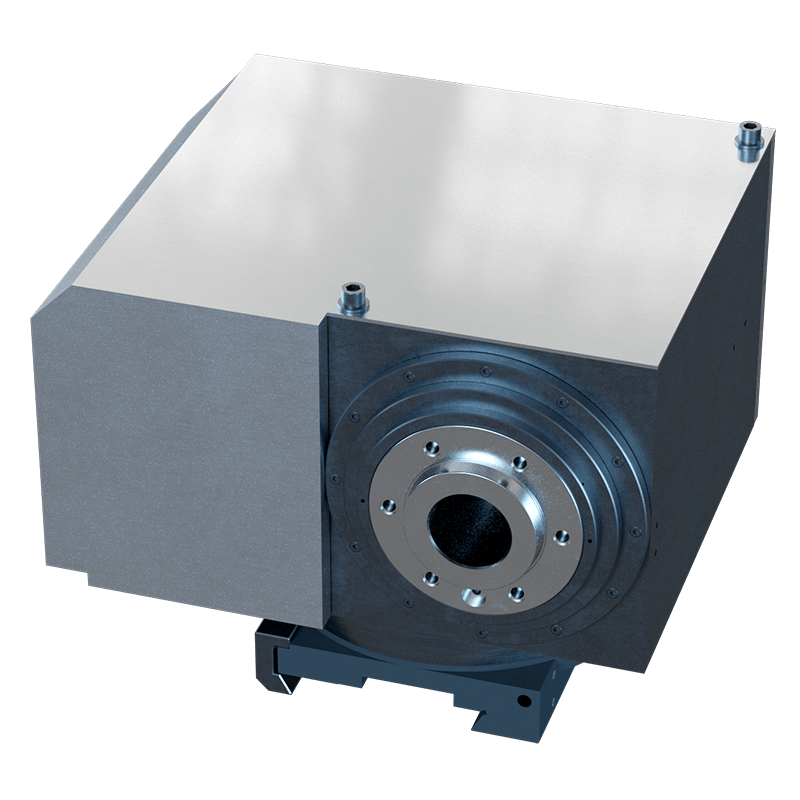

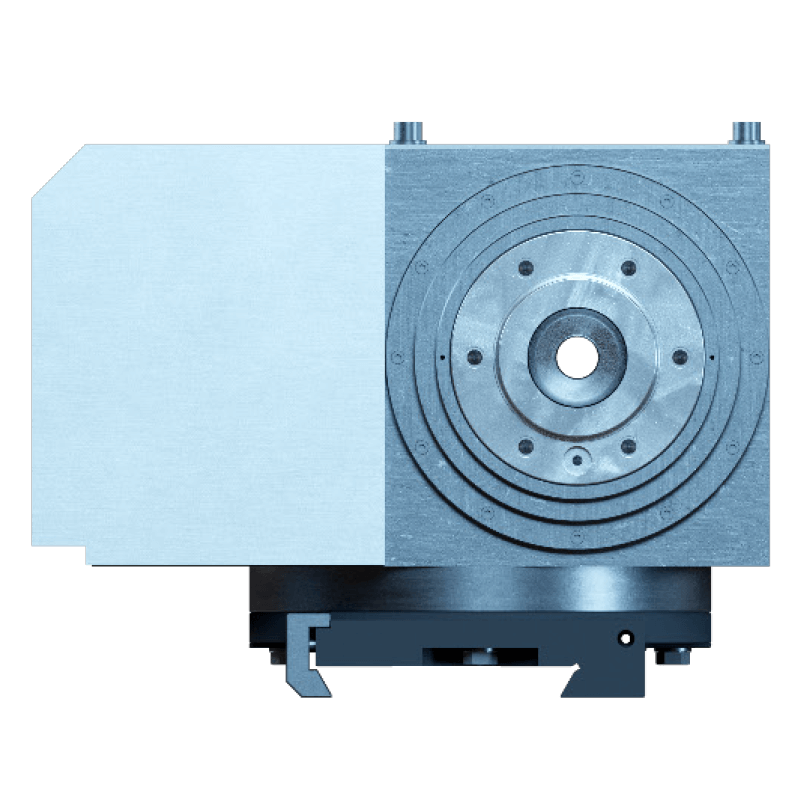

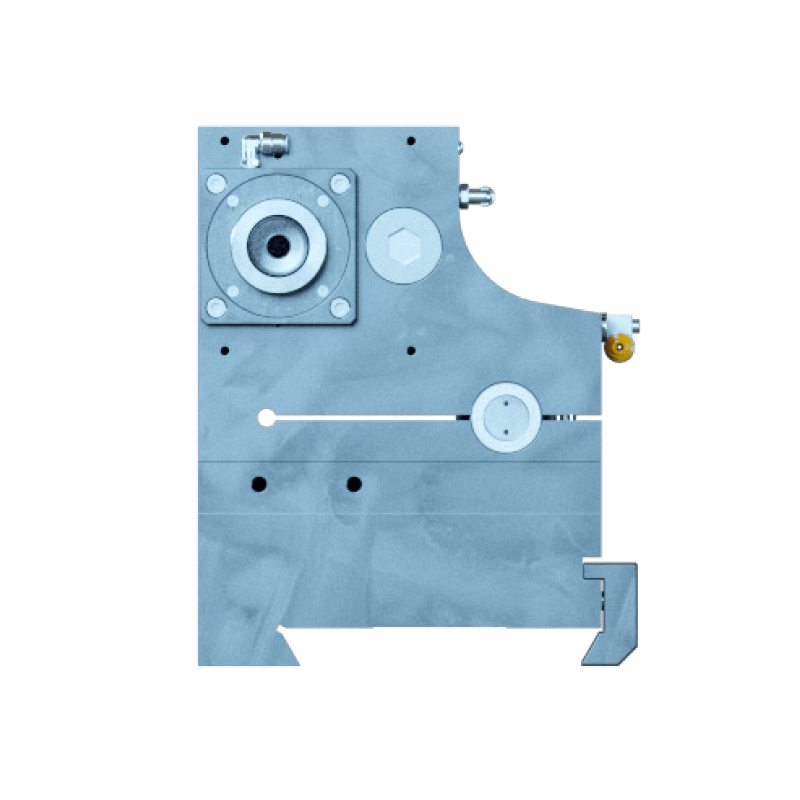

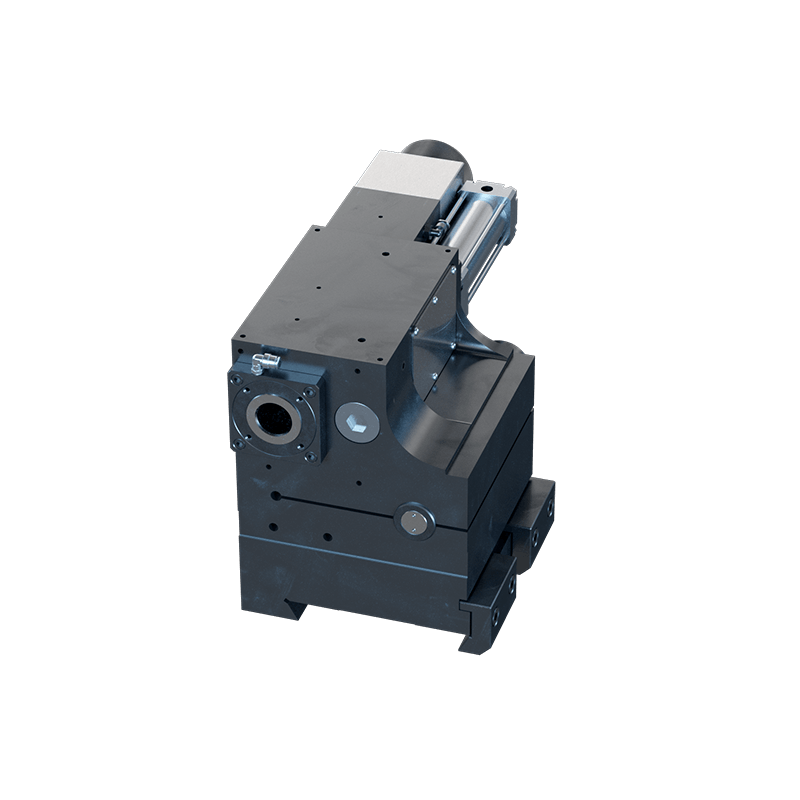

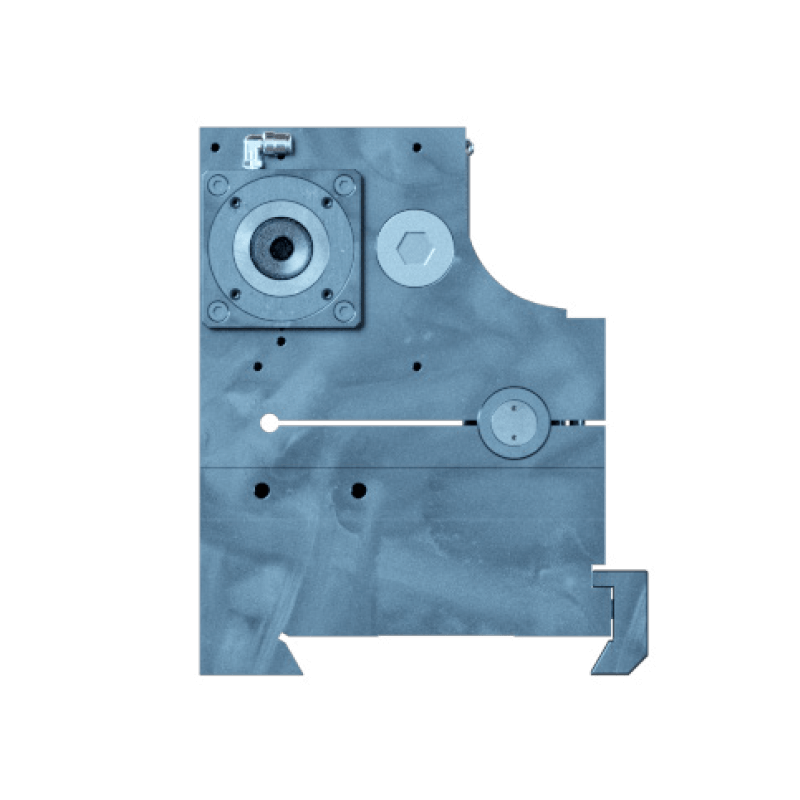

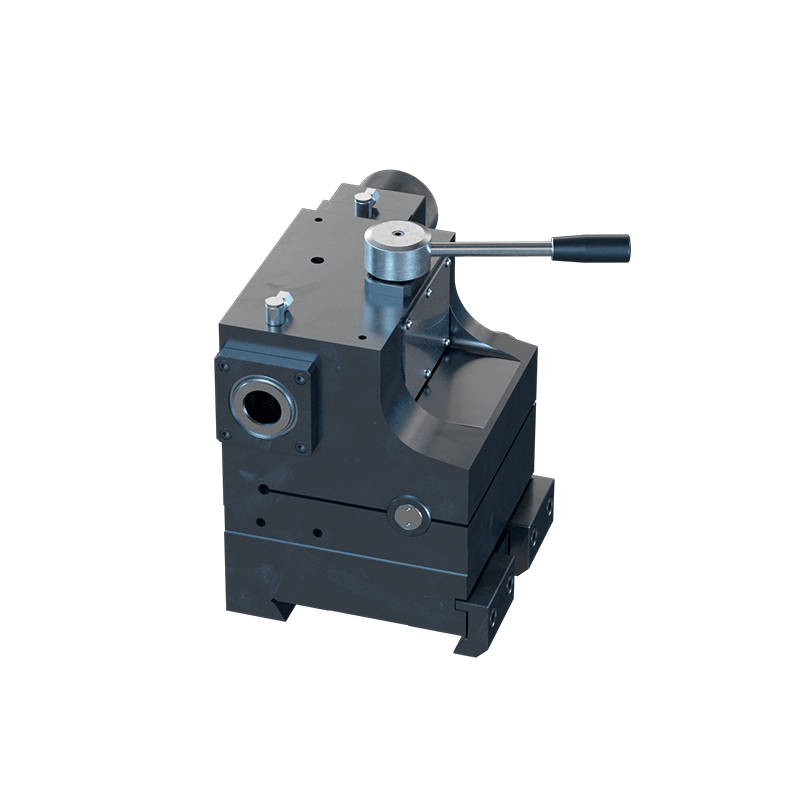

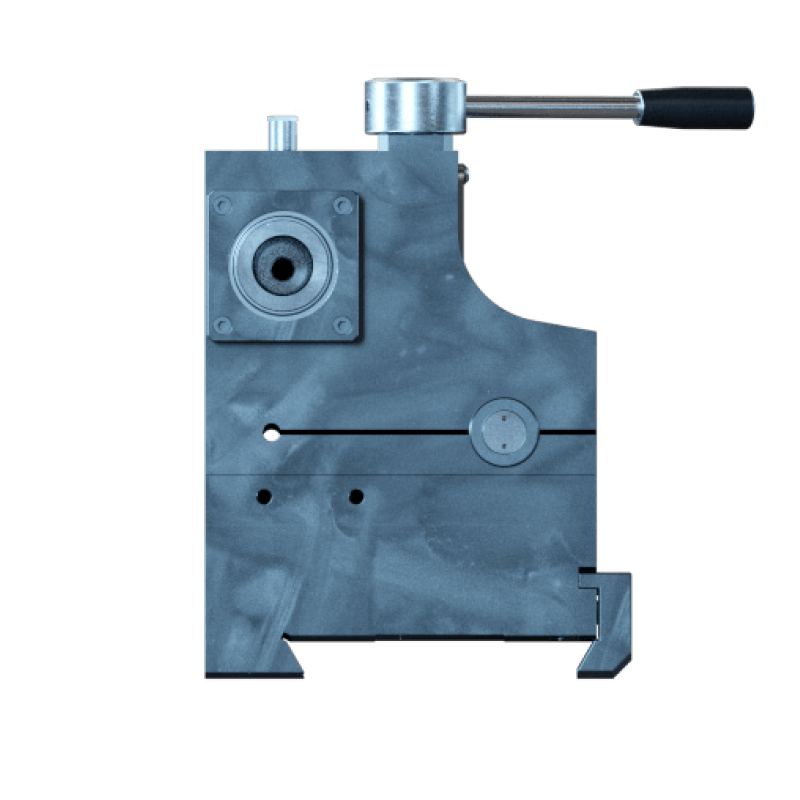

- Internal cylindrical grinding machine IG IS

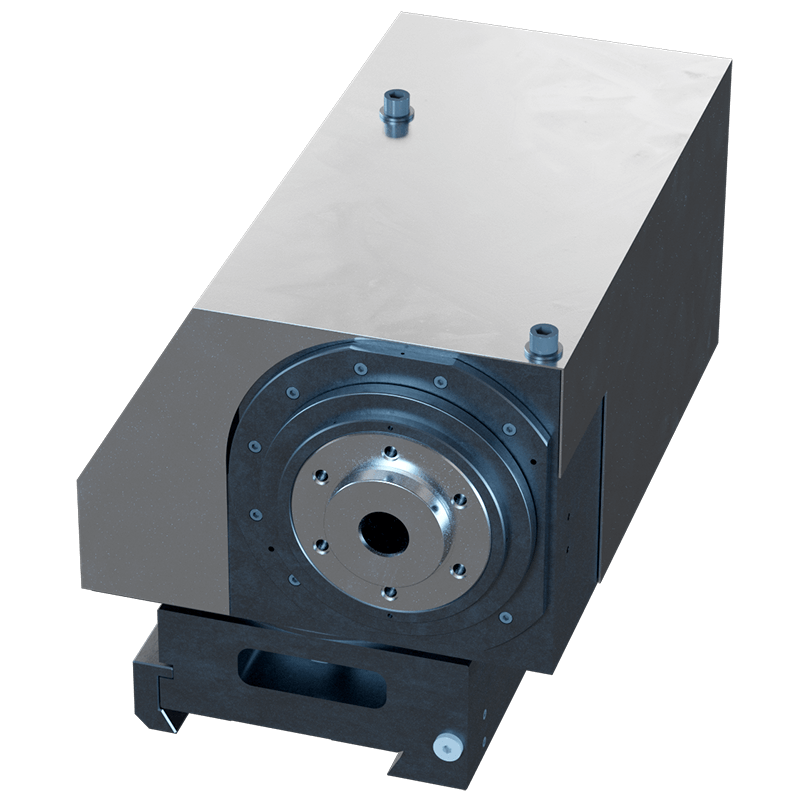

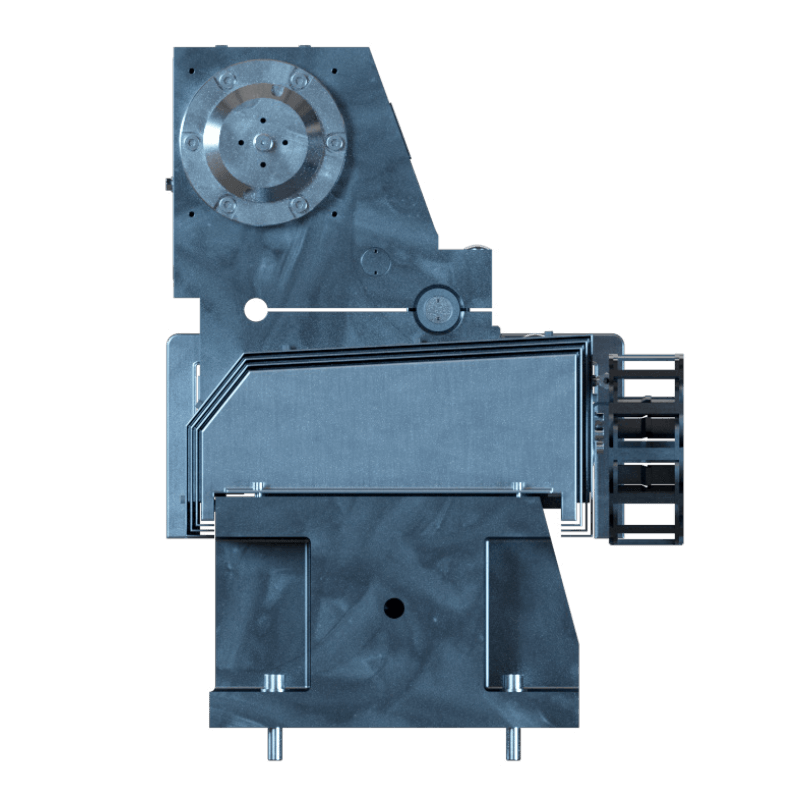

- Internal cylindrical grinding machine IG IM

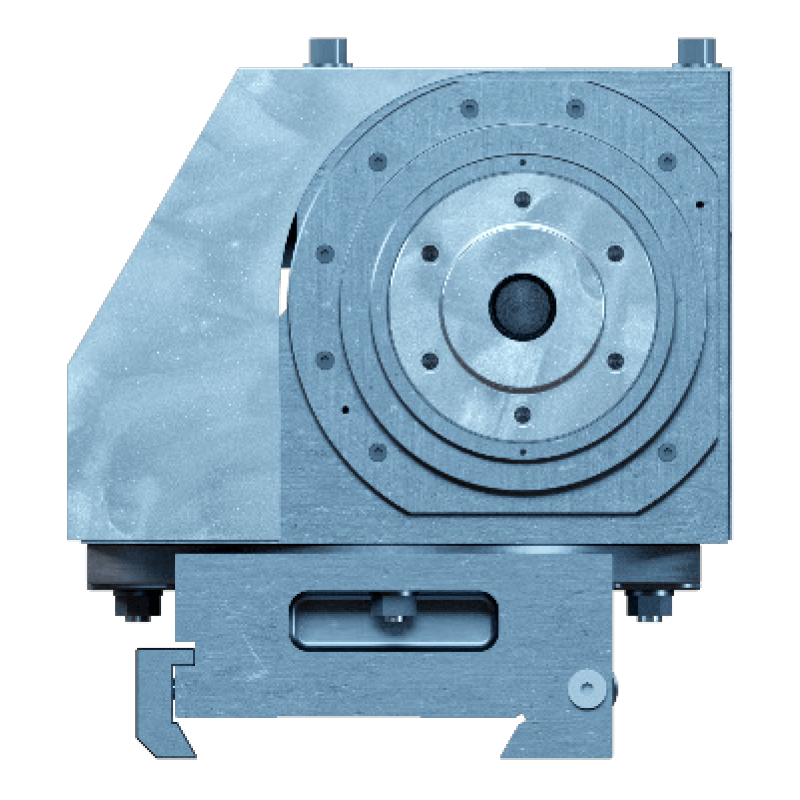

- Internal cylindrical grinding machine IG IL

- Software

- Representatives Offices

- Success factors

- About us