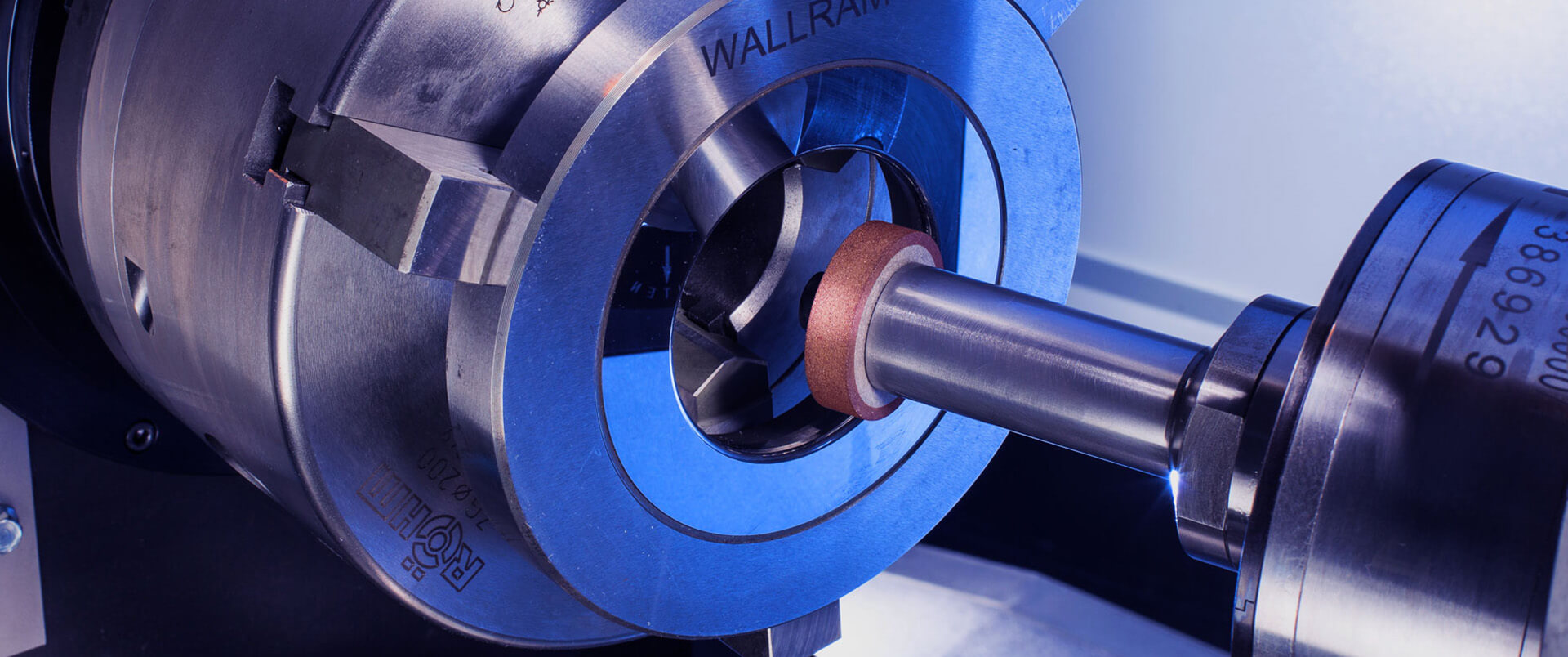

- Grinding machines

- Grinding machines overview

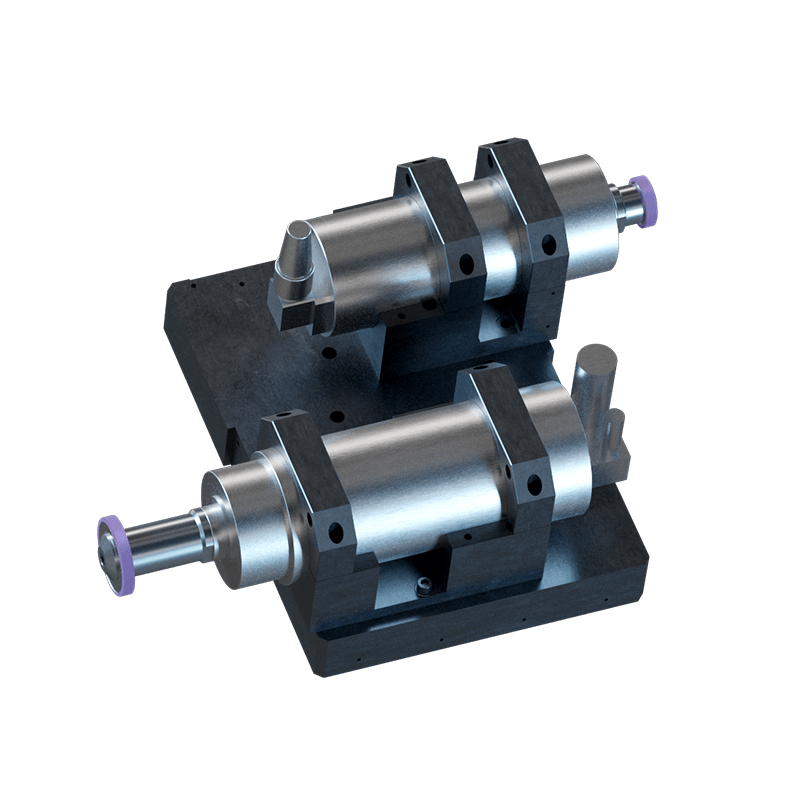

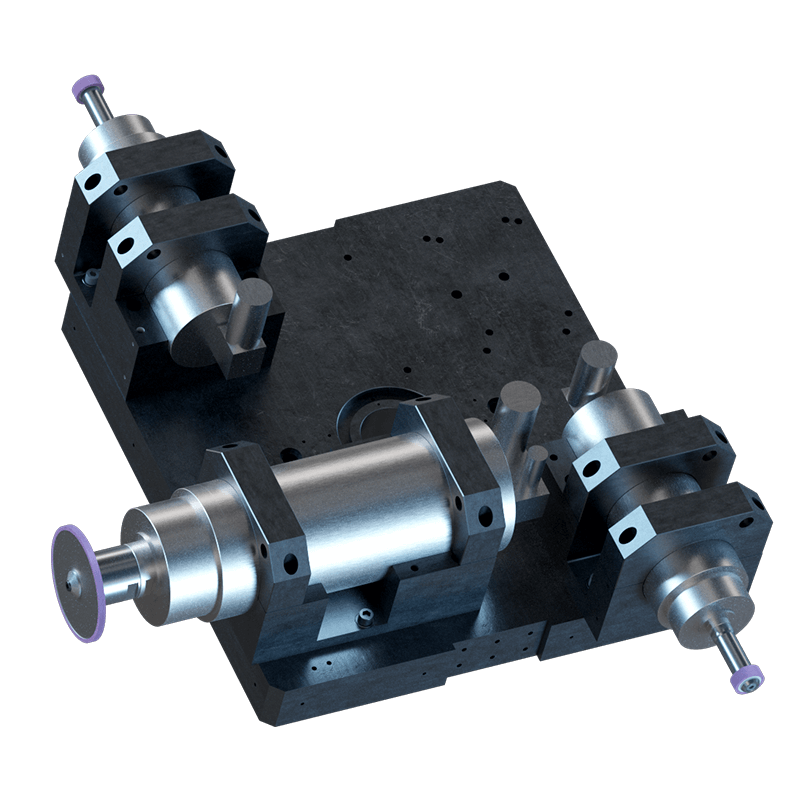

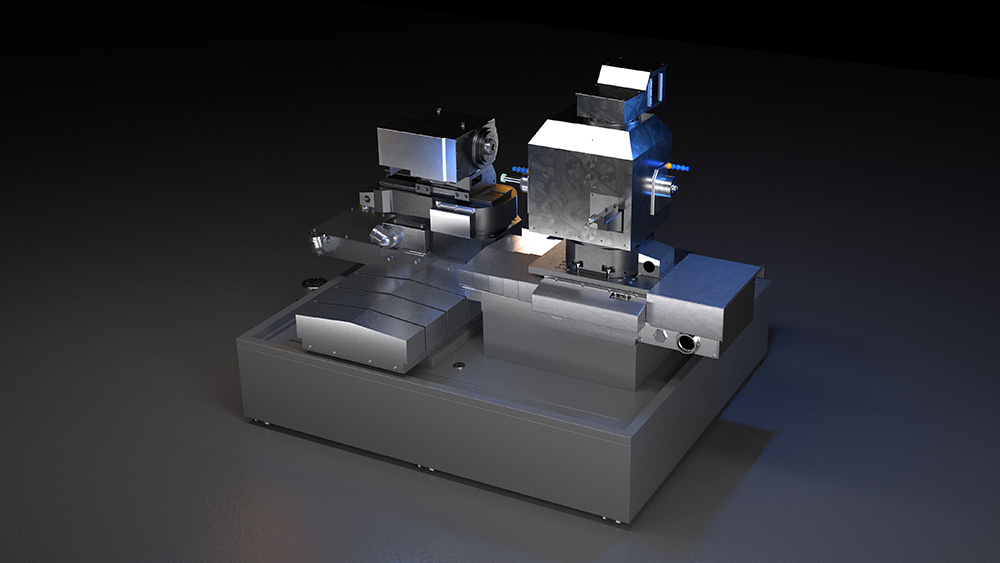

- Cylindrical grinding machine IG FXS

- Cylindrical grinding machine IG FS

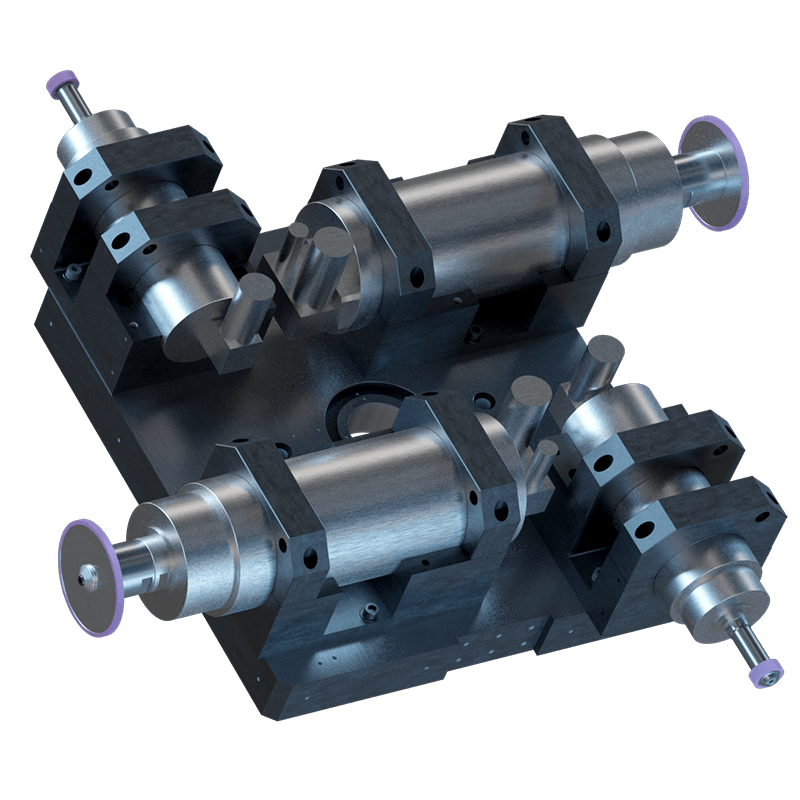

- Cylindrical grinding machine IG FM

- Cylindrical grinding machine IG FL

- Cylindrical grinding machine IG FXL

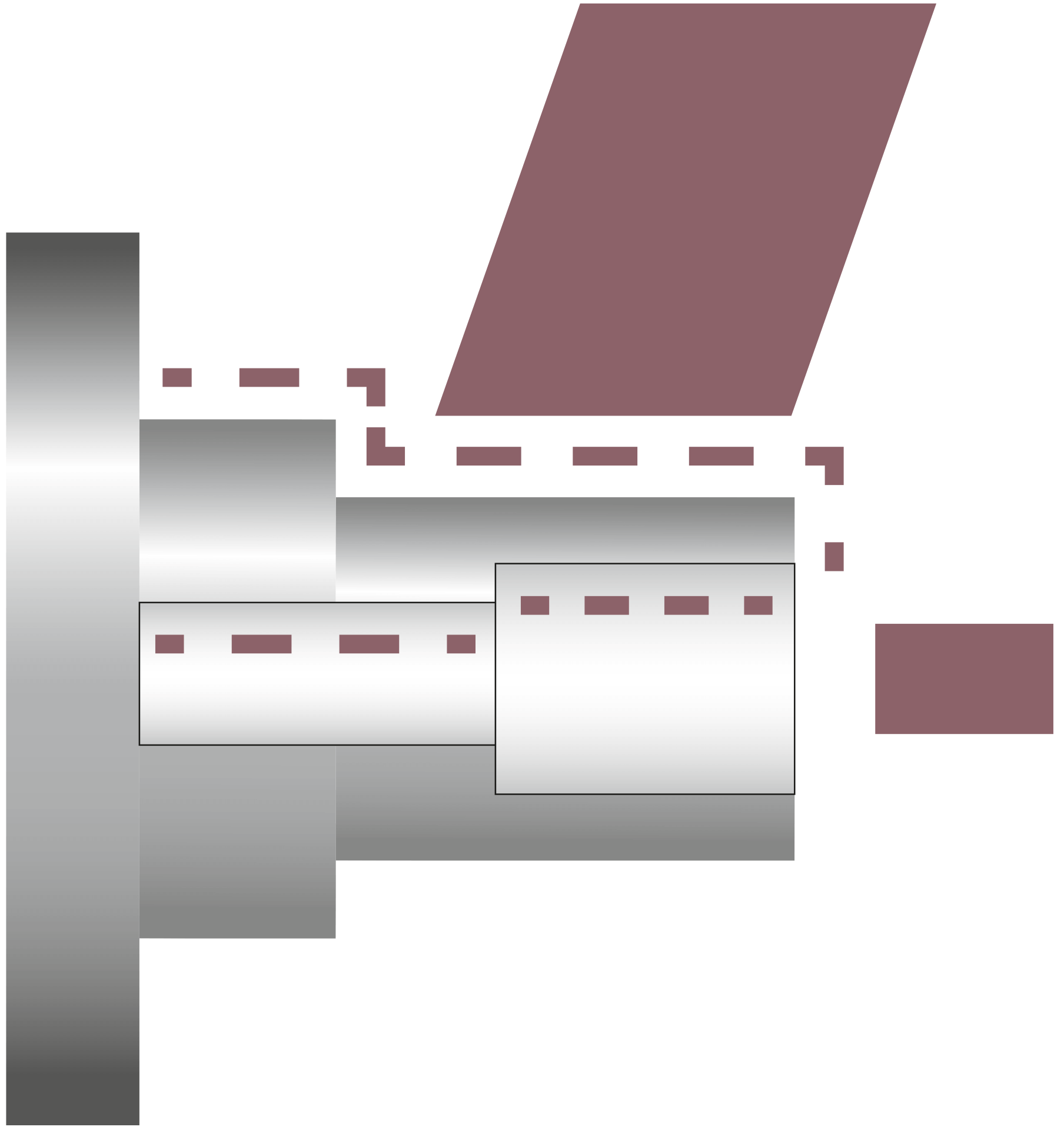

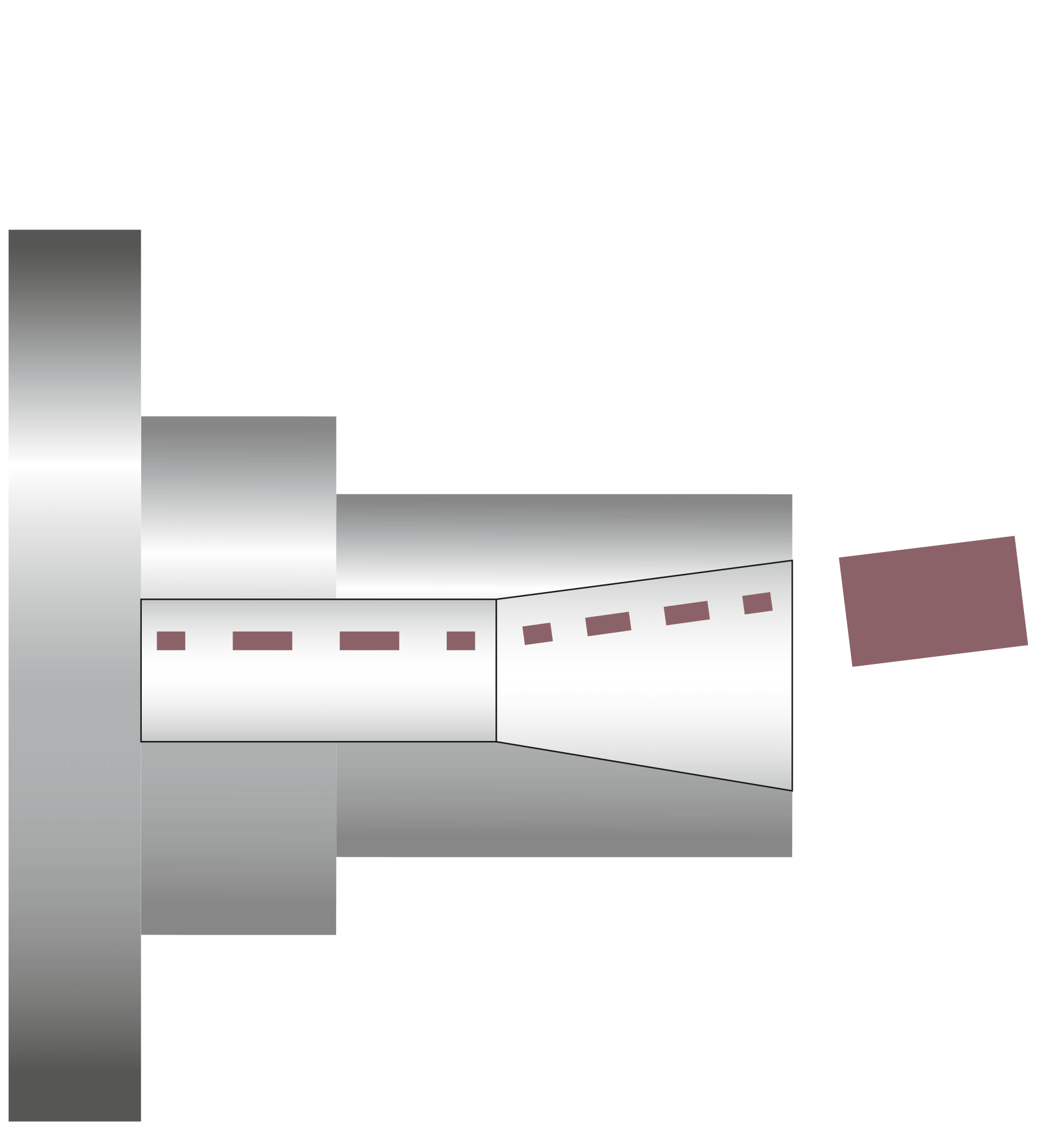

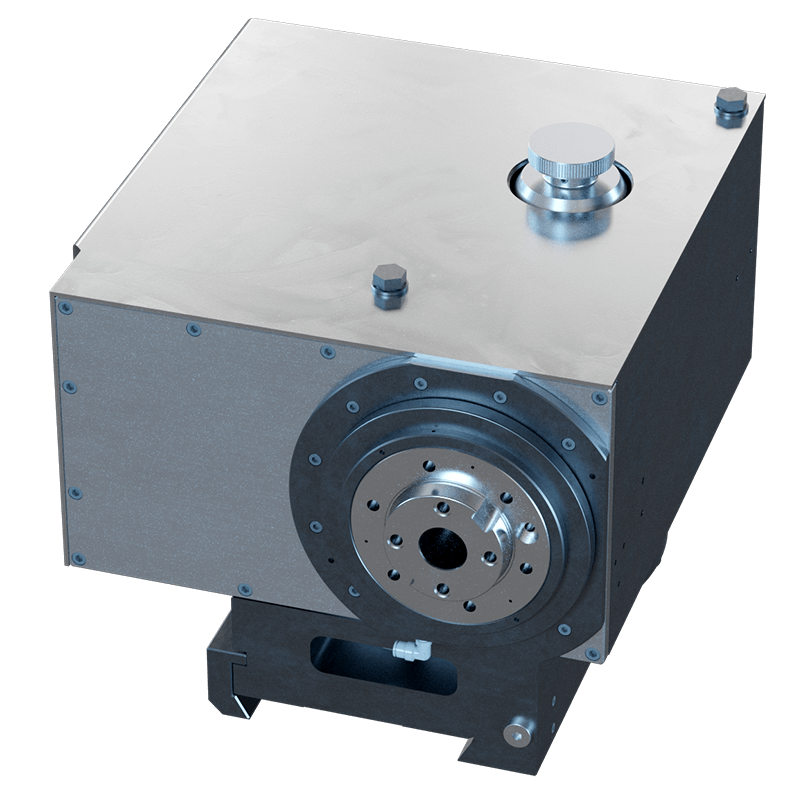

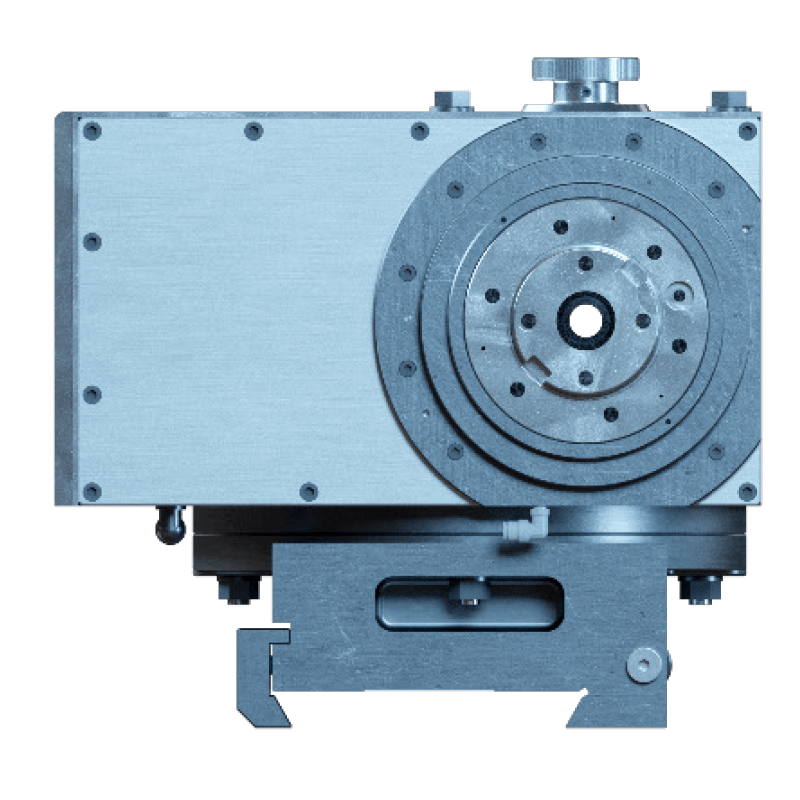

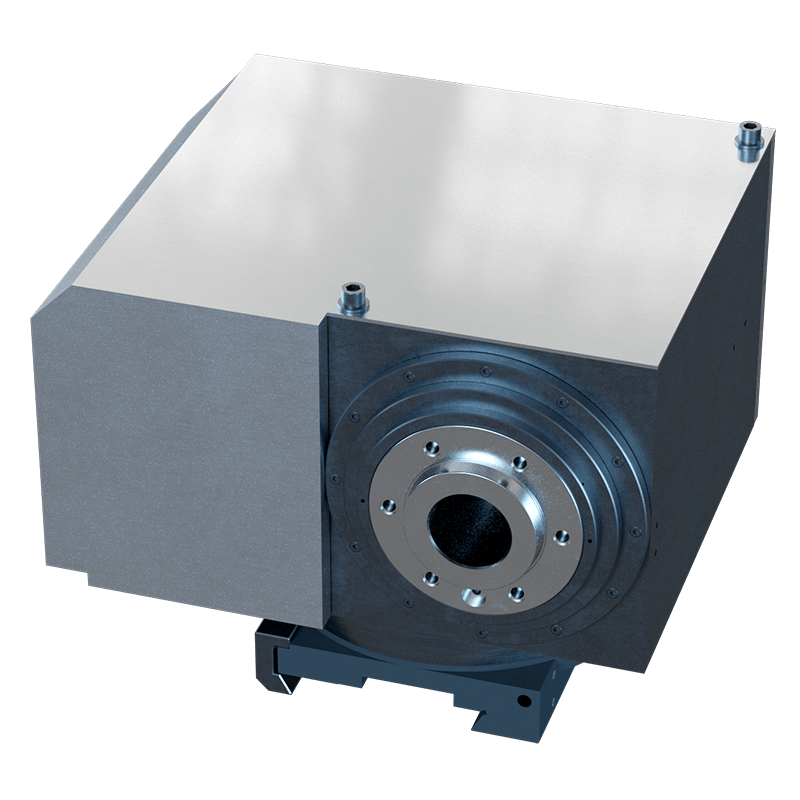

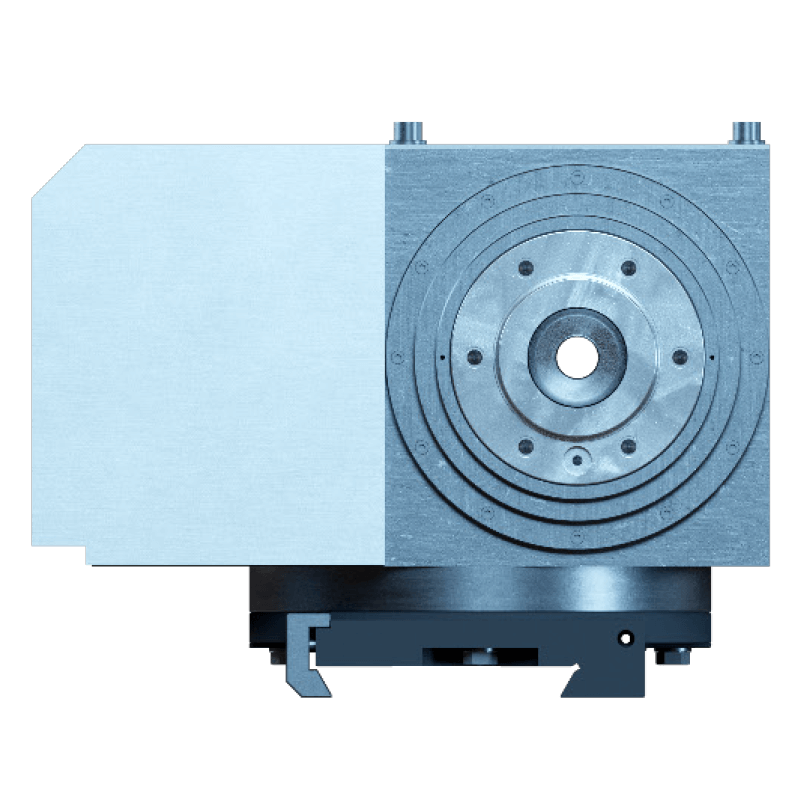

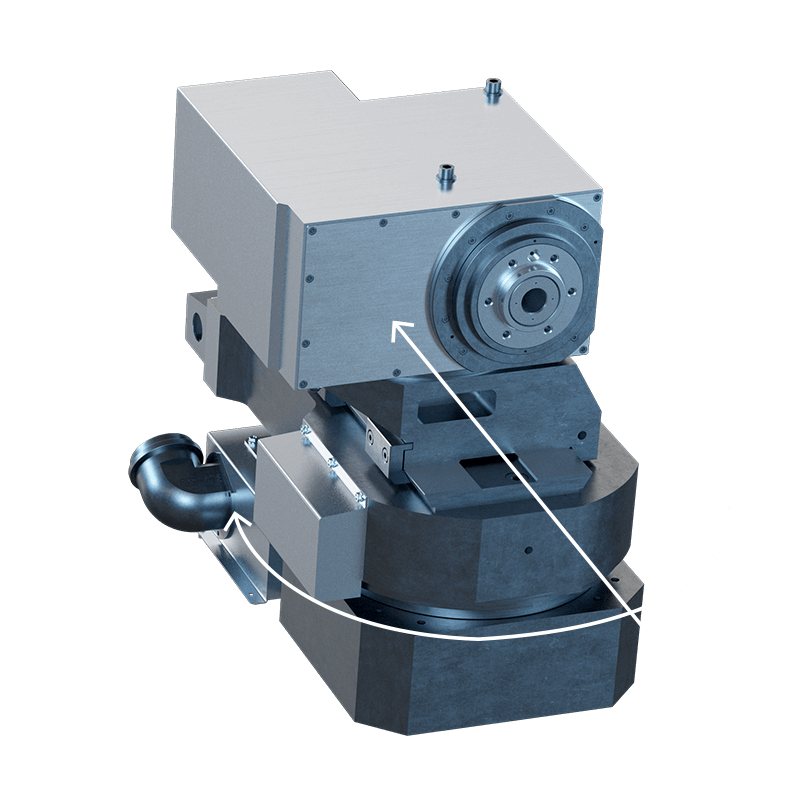

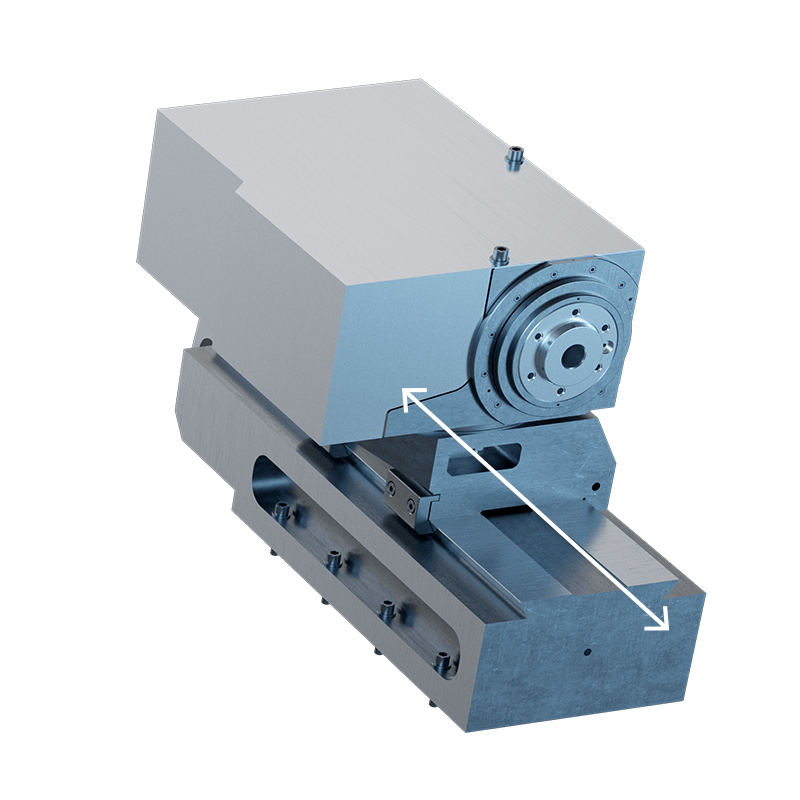

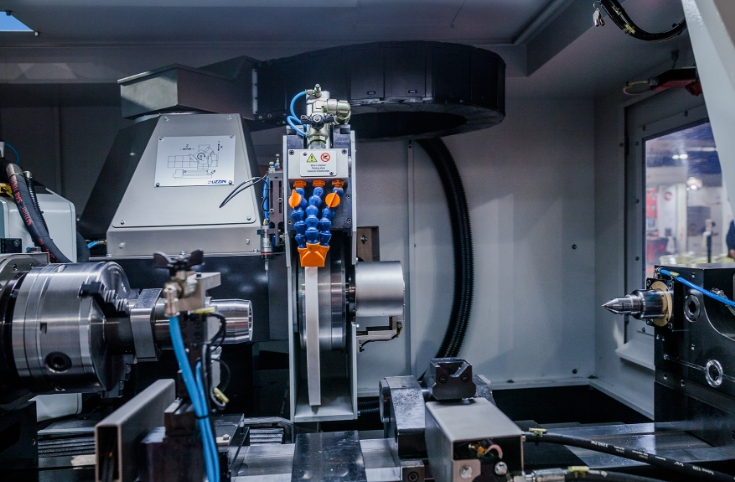

- Internal cylindrical grinding machine IG IS

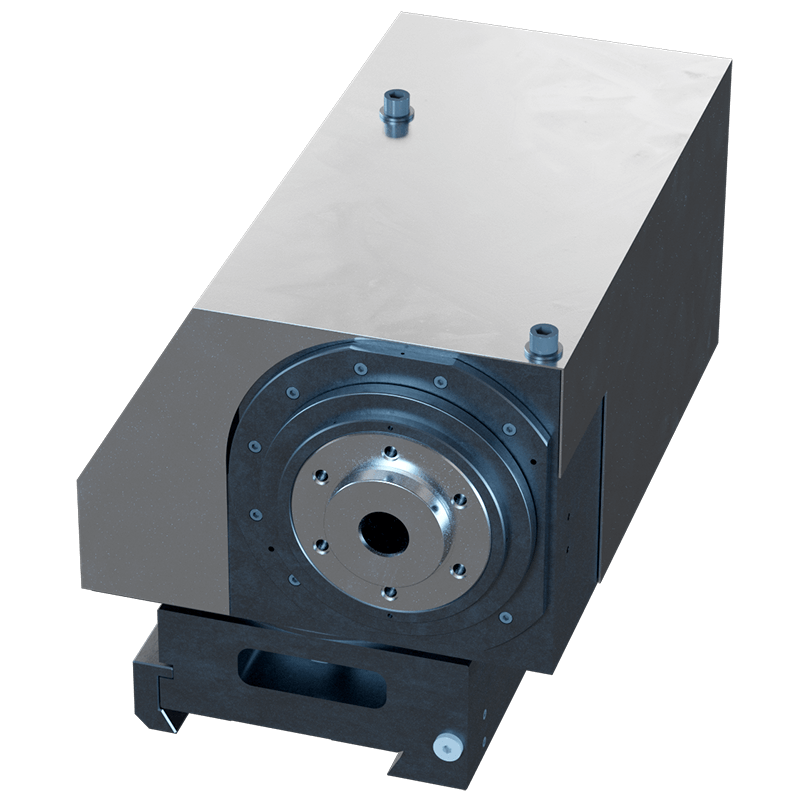

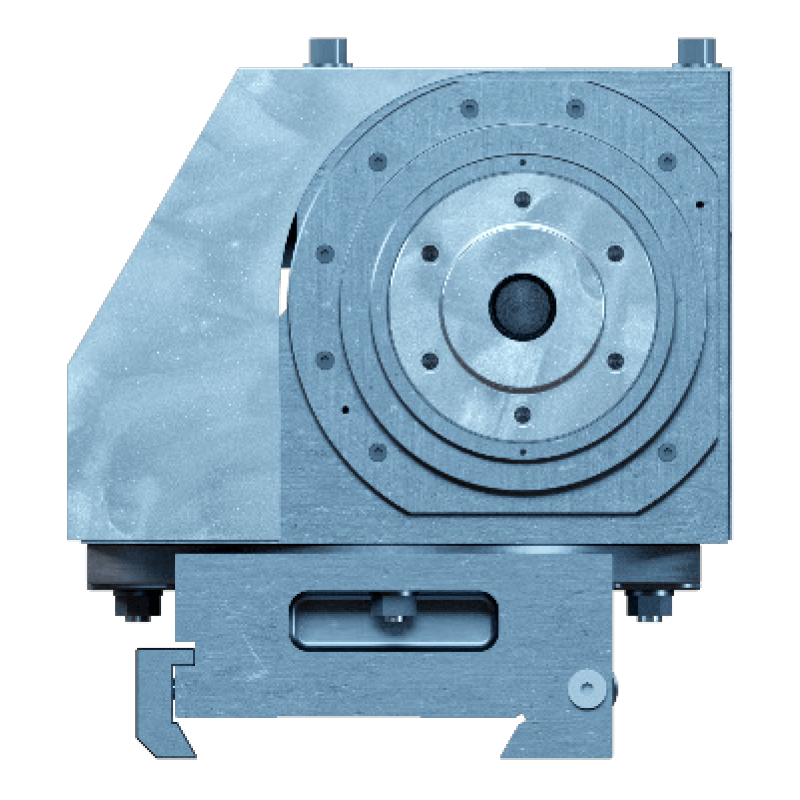

- Internal cylindrical grinding machine IG IM

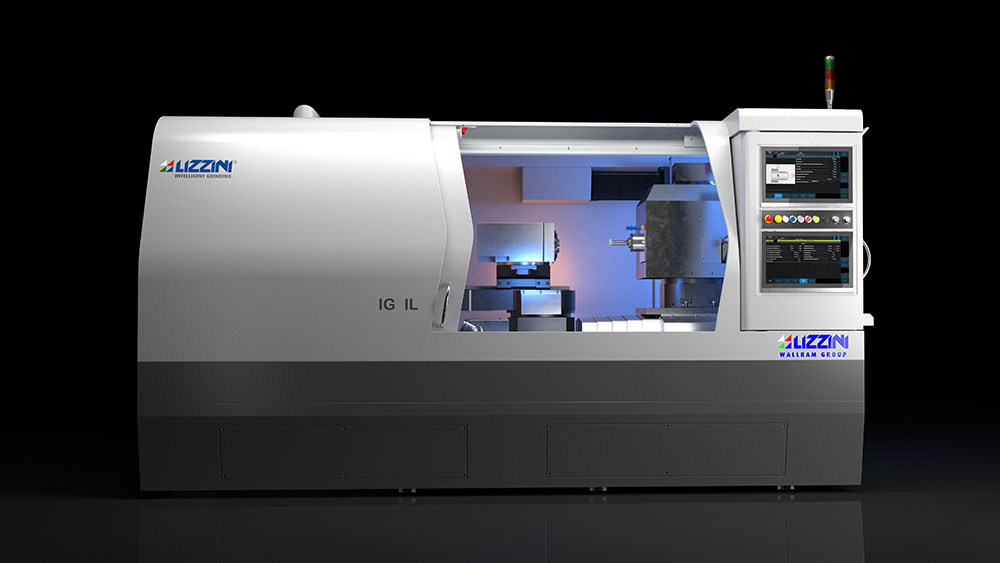

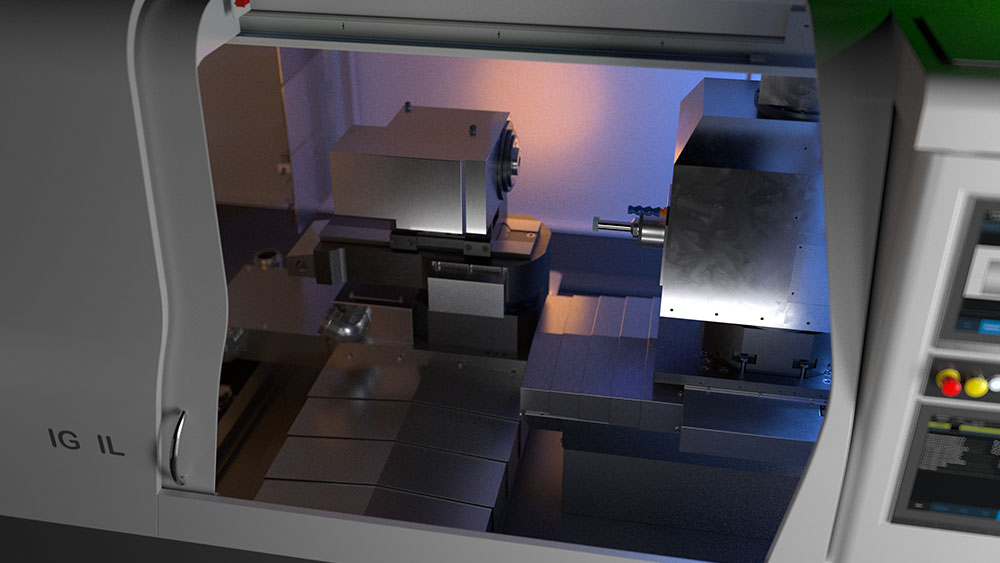

- Internal cylindrical grinding machine IG IL

- Software

- Representatives Offices

- Success factors

- About us